Ithreyi yekhebulaidlala indima ebalulekile ekuphathweni kahle nangokuphephile kwezintambo nezintambo ezindaweni ezahlukene zezimboni nezentengiselwano. Ihlinzeka ngokusekelwa, ukuvikelwa, kanye nokuhlela izintambo, okusebenza njengendlela engcono kakhulu kunezindlela zendabuko ezifana nezinhlelo zemibhobho. Ukukhetha izinto zamathileyi ezintambo kubalulekile ekunqumeni ukuqina kwazo, ukumelana nokugqwala, kanye nokusebenza okuphelele. Lesi sihloko sihlose ukuqhathanisa izinzuzo kanye nokungalungi kwezinketho ezimbili ezidumile:ithreyi yekhebula le-aluminiumfuthiithreyi yekhebula lensimbi engagqwali.

Amathreyi ekhebula le-aluminium aziwa kabanzi ngobulula bawo nokuqina kwawo. Isisindo sawo esiphansi senza kube lula ukuwafaka, kunciphisa izindleko zomsebenzi nezokuthutha. Njengoba engewona amandla kazibuthe, amathreyi e-aluminium awusizo kakhulu ezindaweni lapho ukuphazamiseka kwe-electromagnetic kungabangela khona izinkinga. Aphinde amelane nokugqwala ngokwemvelo, ngenxa yokwakheka kwengqimba ye-oxide evikelayo ebusweni bawo. Leli khwalithi liwenza afaneleke ukusetshenziswa ngaphandle, njengoba engakwazi ukumelana nezimo zezulu ezinzima, okuhlanganisa nemisebe ye-UV. Ngaphezu kwalokho, amathreyi ekhebula le-aluminium avame ukuba nokuqedwa okubushelelezi nobuhle, okwenza abe ukukhetha okukhangayo kokufakwa okuningi.

Kodwa-ke, amathreyi ekhebula le-aluminium nawo anezinkinga ezimbalwa. Nakuba ekwazi ukumelana nokugqwala, awavikelekile ngokuphelele kukho. Ezindaweni ezigqwala kakhulu, amathreyi e-aluminium angadinga izinyathelo ezengeziwe zokuvikela, njengezimbozo, ukuvimbela umonakalo. Okunye okufanele kucatshangelwe amandla aphansi omshini uma kuqhathaniswa nezinye izinto, okungase kunciphise umthamo wazo wokuthwala umthwalo. Ngakho-ke, kubalulekile ukuhlola isisindo kanye nenani lamakhebula ukuqinisekisa ukuthi ithreyi ingazisekela ngokwanele.

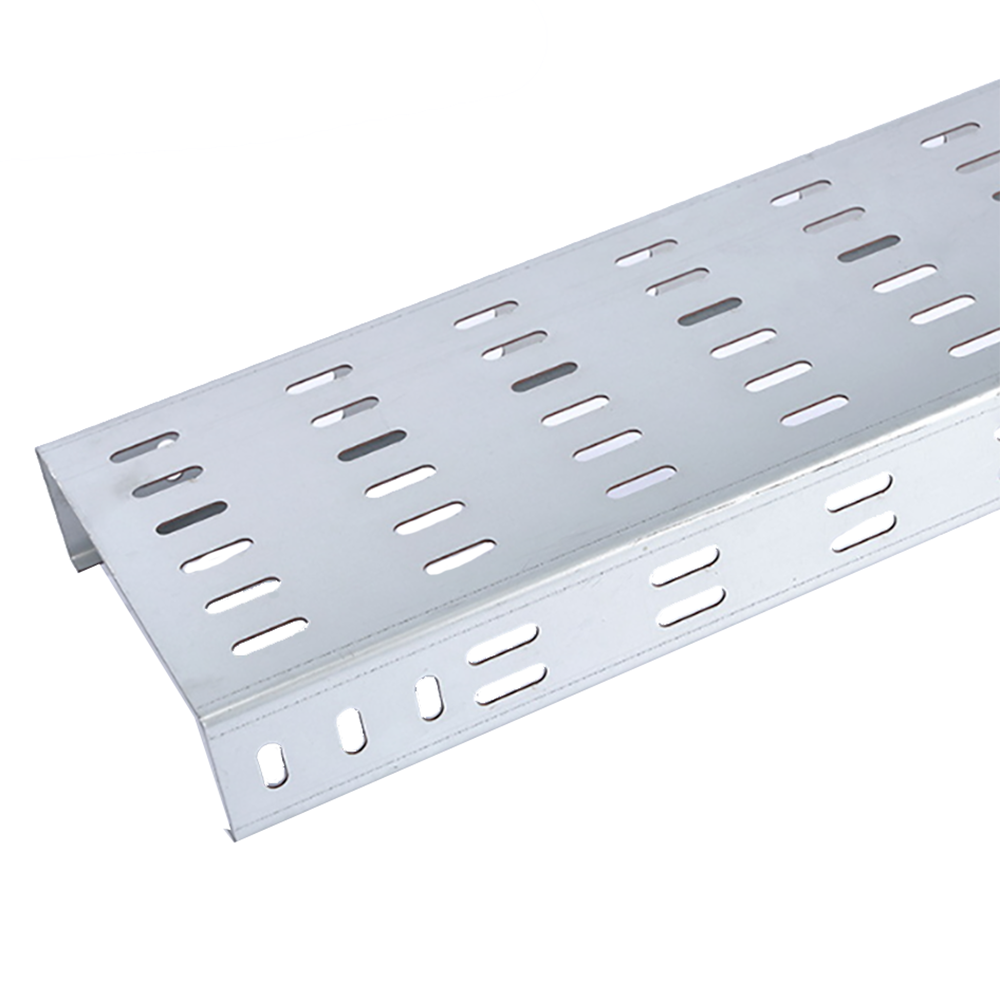

Ngakolunye uhlangothi, amathreyi ekhebula lensimbi engagqwali anikeza amandla nokuqina okuhle kakhulu. Anamandla okuthwala umthwalo omkhulu futhi angathwala izintambo ezisindayo nezinhlelo zokuxhuma. Ngaphezu kwalokho, amathreyi ensimbi engagqwali anokumelana okungavamile nokugqwala, okwenza afaneleke ezindaweni ezidinga kakhulu, kufaka phakathi izitshalo zamakhemikhali kanye nokufakwa ogwini lolwandle. Ukumelana kwawo nokugqwala kuthuthukiswa kakhulu yizinketho zokumboza okukhethekile kanye nokuqedwa, njenge-galvanization efakwe ngokushisa.Amathreyi ekhebula lensimbi engagqwalifuthi zigcina ubuqotho bazo ngisho nasemazingeni okushisa aphezulu, okwenza zibe ukukhetha okuthembekile ekufakweni okulinganiselwe ngomlilo.

Nakuba amathreyi ekhebula lensimbi engagqwali enezinzuzo eziningi, anezinkinga ezimbalwa. Okubaluleke kakhulu ukuthi izindleko zawo ziphezulu uma kuqhathaniswa namathreyi e-aluminium. Insimbi engagqwali iyinto esezingeni eliphezulu, efaka isandla ekwandeni kwezindleko zokukhiqiza. Isisindo esengeziwe samathreyi ensimbi engagqwali senza nokuhamba nokufakwa kube nzima futhi kubize kakhulu. Ngaphezu kwalokho, amathreyi ensimbi engagqwali asengozini yokungenwa amandla kagesi, okungaphazamisa izinhlelo ezithile. Ezindaweni ezinezinkundla ezinamandla kagesi, ezinye izinto noma amasu okufaka umhlabathi kungadingeka ukuze kuphathwe ukuphazamiseka kwamandla kagesi ngempumelelo.

Ekuphetheni, amathreyi ekhebula le-aluminium kanye namathreyi ekhebula lensimbi engagqwali anikeza izinzuzo kanye nokungalungi okuhlukile. Ukukhetha okuphelele kuncike ezintweni ezahlukahlukene njengokusetshenziswa, isabelomali, kanye nezimo zemvelo. Amathreyi ekhebula le-aluminium ahamba phambili ngokukhanya kwawo, ukumelana nokugqwala, kanye nokukhanga kobuhle ngentengo ephansi. Ngakolunye uhlangothi,amathreyi ekhebula lensimbi engagqwaliinikeza amandla aphezulu, ukuqina, kanye nokumelana nezimo ezimbi kakhulu, kuyilapho kubiza kakhulu. Ukuhlola lezi zici nokubonisana nochwepheshe kungasiza ekunqumeni inketho efaneleke kakhulu yephrojekthi ngayinye ethile.

Isikhathi sokuthunyelwe: Okthoba-12-2023