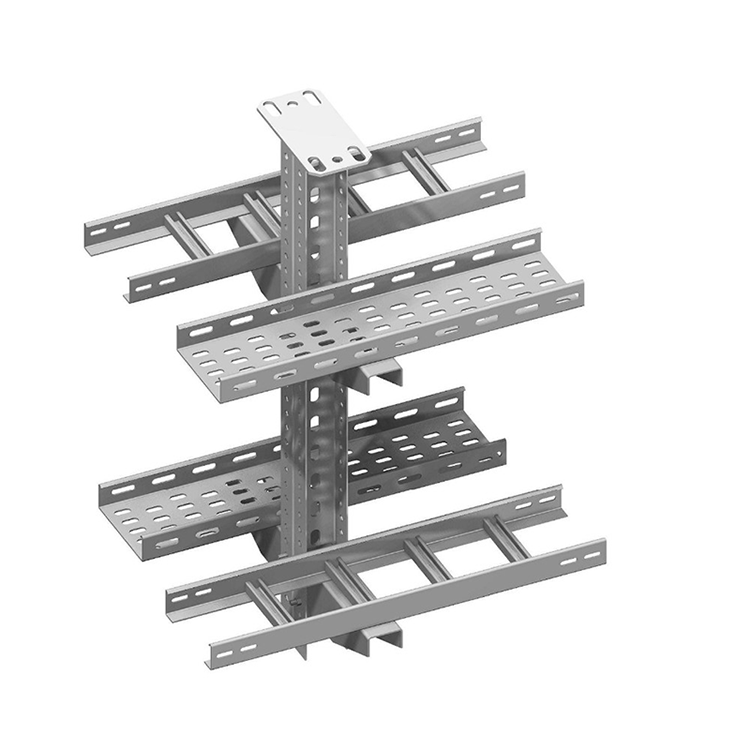

Cable Ladders vs. Cable Trays

Technical Comparison Guide for Industrial Cable Management Solutions

Fundamental Design Differences

| Feature | Cable Ladders | Cable Trays |

|---|---|---|

| Structure | Parallel rails with transverse rungs | Single-sheet metal with slots |

| Base Type | Open rungs (≥30% ventilation) | Perforated/slotted base |

| Load Capacity | Heavy-duty (500+ kg/m) | Medium-duty (100-300 kg/m) |

| Typical Spans | 3-6m between supports | ≤3m between supports |

| EMI Shielding | None (open design) | Partial (25-50% coverage) |

| Cable Accessibility | Full 360° access | Limited side access |

Cable Ladders: Heavy-Duty Infrastructure Solution

Technical Specifications

- Materials: Hot-dip galvanized steel or aluminum alloys

- Rung spacing: 225-300mm (standard), customizable to 150mm

- Ventilation efficiency: ≥95% open area ratio

- Temperature tolerance: -40°C to +120°C

Key Advantages

- Superior load distribution for cables up to 400mm diameter

- Reduces cable operating temperatures by 15-20°C

- Modular components for vertical/horizontal configurations

- Tool-free access reduces modification downtime by 40-60%

Industrial Applications

- Power plants: Main feeder lines between transformers and switchgear

- Wind farms: Tower cabling systems (nacelle-to-base)

- Petrochemical facilities: High-current supply lines

- Data centers: Overhead backbone cabling for 400Gbps fiber

- Industrial manufacturing: Heavy machinery power distribution

- Transportation hubs: High-capacity power transmission

Cable Trays: Precision Cable Management

Technical Specifications

- Materials: Pre-galvanized steel, 316 stainless steel, or composites

- Perforation patterns: 25x50mm slots or 10x20mm micro-perfs

- Side rail height: 50-150mm (containment grade)

- Special features: UV-resistant coatings available

Functional Advantages

- 20-30dB RF attenuation for sensitive instrumentation

- Integrated divider systems for power/control/data separation

- Powder-coated finishes (RAL color matching)

- Prevents cable sag exceeding 5mm/m

Application Environments

- Laboratory facilities: NMR/MRI equipment signal lines

- Broadcast studios: Video transmission cabling

- Building automation: Control networks

- Cleanrooms: Pharmaceutical manufacturing

- Retail spaces: POS system cabling

- Healthcare: Patient monitoring systems

Technical Performance Comparison

Thermal Performance

- Cable ladders reduce ampacity derating by 25% in 40°C environments

- Trays require 20% larger cable spacing for equivalent heat dissipation

- Open design maintains cable temperatures 8-12°C lower in high-density installations

Seismic Compliance

- Ladders: OSHPD/IBBC Zone 4 certification (0.6g lateral load)

- Trays: Typically Zone 2-3 certification requiring additional bracing

- Vibration resistance: Ladders withstand 25% higher harmonic frequencies

Corrosion Resistance

- Ladders: HDG coating (85μm) for C5 industrial atmospheres

- Trays: Stainless steel options for marine/coastal installations

- Salt spray resistance: Both systems achieve 1000+ hours in ASTM B117 testing

Selection Guidelines

Choose Cable Ladders When:

- Spanning >3m between supports

- Installing cables >35mm diameter

- Ambient temperatures exceed 50°C

- Future expansion is anticipated

- High cable density requires maximum ventilation

Opt for Cable Trays When:

- EMI-sensitive equipment is present

- Aesthetic requirements dictate visible installation

- Cable weights are <2kg/meter

- Frequent reconfiguration isn’t anticipated

- Small diameter wiring requires containment

Industry Compliance Standards

Both systems meet these critical certifications:

- IEC 61537 (Cable Management Testing)

- BS EN 50174 (Telecommunications Installations)

- NEC Article 392 (Cable Tray Requirements)

- ISO 14644 (Cleanroom ESD Standards)

- ATEX/IECEx (Explosive Atmosphere Certification)

Professional Recommendation

For hybrid installations, use ladders for backbone distribution (≥50mm cables) and trays for final drops to equipment. Always conduct thermal imaging scans during commissioning to verify ampacity compliance.

Engineering Note: Modern composite solutions now combine ladder structural strength with tray containment features – consult specialists for mission-critical applications requiring hybrid performance characteristics.

→ For all products,services and up to date information,please contact us.

Post time: Aug-15-2025