An Overview of Cable Trays and Common Types

In the operation of large-scale commercial facilities, proper power distribution is crucial to ensuring smooth functionality. Whether in plants, manufacturing workshops, or data centers, a highly efficient system is required to achieve stable transmission of electricity, with cables serving as a key component in enabling this function.

The Role of Cable Trays

Faced with complex cable networks, a reliable wiring management system is essential for maintaining power supply operations. As a modern alternative to wire ducts and traditional conduits, cable trays are one of the most widely used systems of this kind.

This article provides a comprehensive introduction to the basic concepts, common types, main functions, and advantages of cable trays, helping readers better understand and select the appropriate cable tray system.

What Are Cable Trays?

Cable trays, also known as cable brackets, are mechanical structural systems designed to centrally support large cable networks. They provide a sturdy, durable, and reliable laying environment for various types of power cables and complex wiring, widely used in managing power cables, armored cables, communication cables, fiber optic cables, and more.

With cable trays, wires can be laid safely while saving time and costs. Their installation is simple, requires no advanced technical expertise, and allows for relatively easy management of complex cable networks. A variety of cable tray types are available on the market, each suited to different scenarios.

Primary Uses of Cable Trays

The core value of cable trays lies in their effective support and protection of power and signal cables, while facilitating upgrades, expansions, adjustments, and relocations of cable networks.

The open structure of cable trays promotes heat dissipation, offering an advantage over enclosed conduit systems by effectively avoiding overheating risks. Additionally, cable trays can be installed in exposed locations such as ceilings and walls, as well as underground, demonstrating strong adaptability.

Advantages of Cable Trays

Here are some key benefits of using cable trays:

Cost-Effectiveness

Compared to traditional cable protection methods like conduits and wireways, cable trays are more economical and better suited for supporting complex cable structures.

Ease of Maintenance

Cables are visible and potential issues can be easily identified. Wires can be quickly removed and replaced, significantly simplifying daily maintenance tasks.

High Safety

Trays can be installed in hard-to-reach locations, preventing unauthorized access. Cables within trays are easy to label, locate, and replace, with minimal reliance on technical expertise.

Flexibility and Variety

Cable trays come in a wide range of types, allowing users to select the most suitable one based on actual needs.

Common Types of Cable Trays

The following are the most common types of cable trays available today:

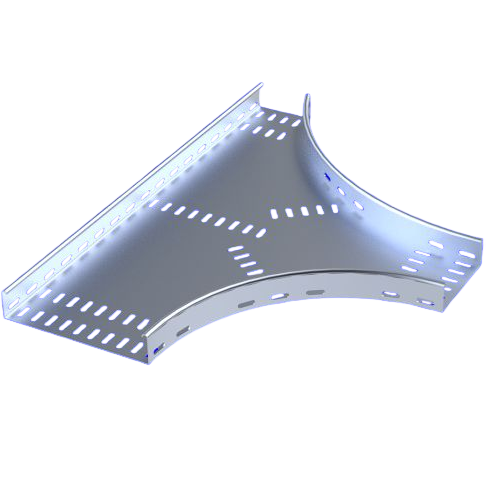

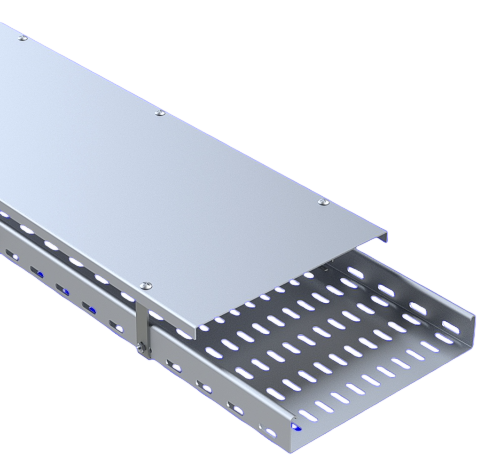

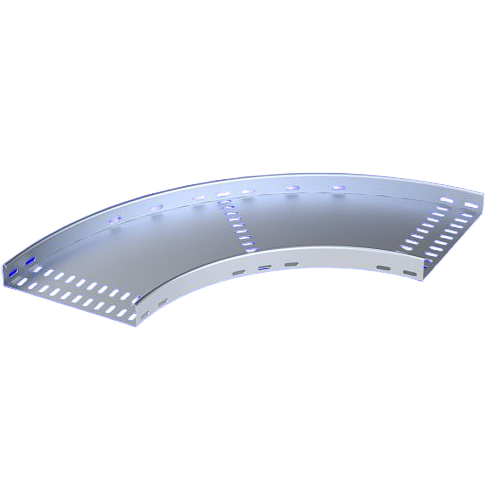

- Ladder-Type Cable Trays

Characterized by two side rails connected by rungs, ladder-type trays are widely used and allow access to cables from both above and below. The perforated rungs provide anchor points for tying and securing cables, while the open design prevents moisture accumulation.- Perforated Cable Trays

These trays feature a perforated base plate that supports the cables placed within. They are commonly used for instrumental and power cables, particularly where cable longevity is a priority. The perforated design isolates cables while ensuring proper ventilation to prevent overheating.- Solid-Bottom Cable Trays

Primarily used for fiber optic cables, these trays have a smooth, unperforated base plate running along longitudinal side rails. They can support all types of cables and wires. While the solid structure prevents heat buildup, it may trap moisture—a issue that can be mitigated with custom perforations.- Wire Mesh Cable Trays (Basket Trays)

Made from stainless steel wires woven into a basket-like mesh, these trays are lightweight and feature an open design. They are commonly used for low-voltage cables, communication wires, and fiber optic cables.- Channel Cable Trays

With a relatively narrow width, channel trays are mainly used to support short-distance vertical cable drops, typically carrying one or two cables to nearby equipment. Their compact structure prevents cable sagging, offering an economical and durable alternative to other cable protection methods.

Conclusion

Cable trays serve as an ideal solution for electrical and network engineers managing small to large-scale cable structures, offering cost-effectiveness, adaptability, and durability. It is recommended to select the most suitable type based on actual project requirements by referring to the types discussed above.

→ For all products,services and up to date information,please contact us.

mailto:mollygong@shqinkai.com

Post time: Sep-08-2025