Cable Trays Compared: Perforated vs. Solid – Selecting the Optimal System for Your Project

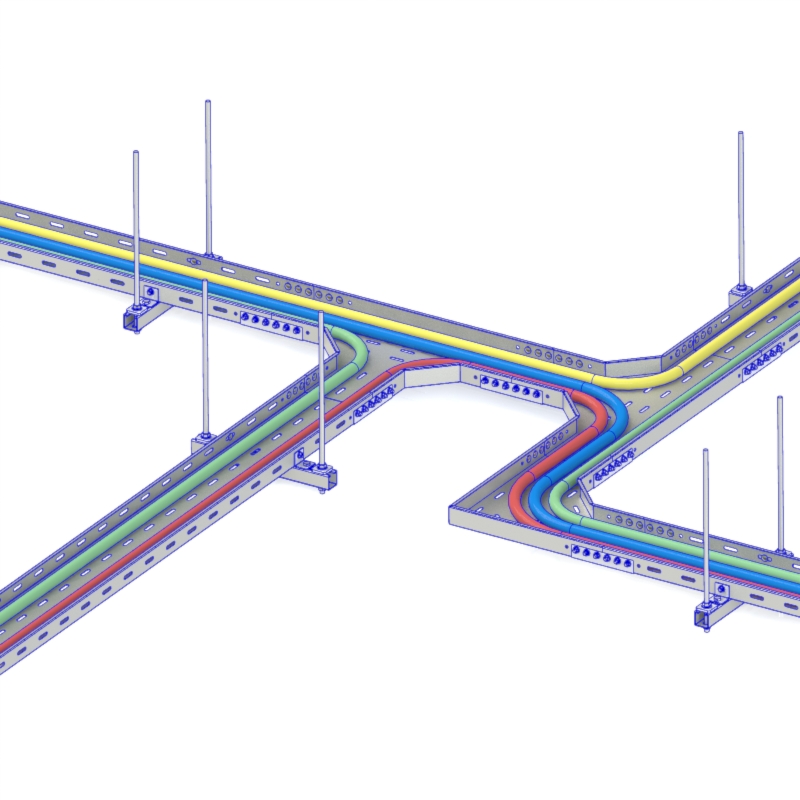

In contemporary infrastructure, cable management systems are a critical component, essential for industrial facilities, commercial complexes, and even large residential buildings. Exposed or haphazard wiring not only compromises a structure’s appearance but also introduces significant safety risks. Cable trays effectively mitigate these concerns, providing a structured solution for organizing cables, ensuring their protection, and facilitating a tidy installation.

At qinkai, a leading cable tray manufacturer in India, we frequently encounter clients deliberating between various tray types, with the choice between perforated and solid designs being a common point of consideration. Both serve distinct purposes, and understanding their fundamental differences is key to selecting the most appropriate system for your specific application. This guide aims to clarify these distinctions, empowering you to make an informed decision that ensures the long-term efficiency and reliability of your cable management infrastructure.

Defining Perforated and Solid Cable Trays

A perforated cable tray is crafted from materials such as stainless steel, aluminum, or galvanized iron (GI). Its defining feature is a pattern of holes or perforations across its surface. This design promotes superior airflow, which is crucial for dissipating heat generated by cables and preventing overheating. The accessible, open structure also simplifies the processes of installation, future inspection, and any necessary modifications like adding or removing cables. Known for their flexibility, these trays are a versatile choice adaptable to projects of varying scales. We at qinkai provide customized solutions, tailoring tray dimensions and perforation patterns to meet precise project requirements.

Key advantages of perforated cable trays include:

Superior ventilation and heat management.

Straightforward cable routing and branching.

Ease of installation, maintenance, and modification.

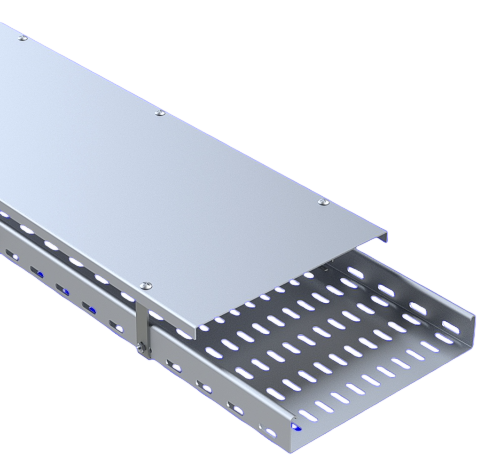

In contrast, a solid cable tray features a fully enclosed, continuous base without any perforations. This sealed design offers a high degree of protection against external elements such as dust, moisture, and potential physical damage. This makes them particularly well-suited for outdoor installations or indoor areas with high contamination risks. While the initial solid cable tray price might be higher due to greater material usage and enhanced protective qualities, the investment is justified in demanding environments.

10 Critical Distinctions: Perforated vs. Solid Trays

The following comparison outlines the core differentiators to guide your selection process:

Feature Perforated Cable Tray Solid Cable Tray

Ventilation Excellent, due to open design. Minimal, as the base is fully enclosed.

Heat Management Actively prevents cable overheating. Can trap heat, potentially requiring additional cooling measures.

Environmental Protection Low to Medium; suitable for clean, controlled spaces. High; shields against dust, moisture, and debris.

Inspection & Maintenance Easy and direct access to cables. Often requires disassembly for access.

Weight Lighter, due to material reduction from perforations. Heavier, because of the continuous material base.

Modifications Simple to adapt, cut, or adjust on-site. More challenging and less flexible to modify.

Cost Generally more budget-friendly. Typically higher, reflecting material and manufacturing costs.

Material Options Includes GI, stainless steel, and aluminum for corrosion resistance. Often may include or require protective coatings.

Appearance Industrial and functional aesthetic. Sleek, enclosed, and visually discreet.

Ideal Application Indoor environments requiring airflow. Outdoor, harsh, or dusty conditions.

Selecting the Ideal Tray for Your Application

Making the correct choice hinges on a careful evaluation of your project’s specific conditions and demands.

Assess the Installation Environment: Is the location indoors in a clean, controlled space, or is it exposed to the elements? Perforated trays excel indoors, while solid trays are built for durability in challenging outdoor or dirty indoor settings.

Determine Cable Load and Heat Generation: Consider the electrical load and the amount of heat the cables will produce. Projects with significant heat output benefit greatly from the ventilated design of perforated trays.

Choose Appropriate Materials: For perforated trays, materials like stainless steel or galvanized iron offer inherent corrosion resistance. Solid trays might necessitate an additional protective coating to ensure longevity in corrosive environments, which can impact the overall cable tray price.

Select the Correct Size: Ensure the chosen tray, whether perforated or solid, has adequate capacity for your current cable needs and allows for potential future expansion.

Factor in Long-term Maintenance: Consider the frequency of anticipated inspections or cable changes. Perforated trays offer significant advantages in accessibility, reducing maintenance time and labor costs.

Conclusion: Making the Strategic Choice

The decision between perforated and solid cable trays is a strategic one, directly impacting system performance, safety, and lifecycle costs. Perforated cable trays are the go-to solution for managing heat and ensuring easy access in controlled environments. Conversely, solid cable trays provide unmatched protection where cables are vulnerable to external contaminants and mechanical threats.

By thoroughly analyzing your project’s environmental conditions, technical requirements, and long-term operational goals, you can confidently select the cable management system that delivers optimal functionality, reliability, and value.

Post time: Nov-14-2025