In-Depth Guide to Cable Tray Types

Cable trays are essential components in electrical wiring systems, providing structured support for cables. Compared to traditional conduits, they offer significant advantages in installation efficiency, maintenance convenience, and overall cost-effectiveness. Below is a detailed introduction to several mainstream cable tray types and their core features.

Ladder-Type Cable Trays

Inspired by the structure of a ladder, these trays consist of two longitudinal side rails connected by transverse rungs. Made from durable materials like aluminum or steel, they ensure long-lasting mechanical strength and durability. The open design not only reduces manufacturing costs but also offers multiple advantages: effective prevention of moisture accumulation, improved heat dissipation, and easy daily inspection and maintenance. It is important to note that this design provides limited shielding against electromagnetic interference.

Ladder-type cable trays are widely used in applications such as wind turbines, solar power systems, data centers, and various industrial and transportation infrastructures.

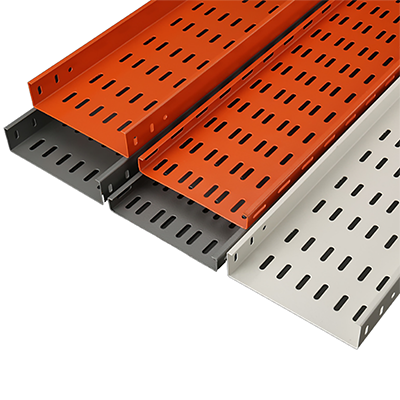

Perforated Cable Trays

These trays feature uniformly distributed ventilation holes on the sides and base, ensuring structural integrity while providing good heat dissipation. Compared to ladder-type designs, they offer a higher degree of enclosure, delivering more comprehensive physical protection for cables while maintaining easy inspection and maintenance.

Perforated cable trays are commonly used in data centers, industrial plants, commercial buildings, and communication facilities.

Wire Mesh Cable Trays

Constructed with a metal mesh structure, these trays offer the best ventilation among all types but provide relatively weaker physical protection. Their standout advantage lies in their exceptional flexibility and modular design, allowing them to be easily cut or bent to meet specific installation requirements.

These trays are primarily used in environments where ventilation and flexibility are critical, such as data centers and communication rooms.

Channel Cable Trays

Featuring a U-shaped cross-section design, these trays can be configured with either perforated or solid bottoms. Their compact size makes them particularly suitable for short-distance wiring or applications with a limited number of cables. The design ensures effective cable protection within confined spaces, making them ideal for commercial offices and other settings where aesthetics are important.

It is worth noting that the industry sometimes differentiates between “channel” and “trough” trays, with the latter typically referring to larger, more robust U-shaped variants.

Solid-Bottom Cable Trays

These trays feature a fully enclosed, non-ventilated base and can be constructed from aluminum or steel (material choice directly impacts weight and cost). This design provides the highest level of physical protection for cables, making them particularly suitable for delicate fiber optic and security wiring. They also effectively suppress electromagnetic interference. However, their drawbacks include relatively limited heat dissipation and ventilation capabilities, and the enclosed base makes installation and maintenance slightly less convenient than open designs.

Why Choose Cable Tray Systems?

Compared to traditional conduit solutions, cable tray systems paired with specialized cables offer the following notable advantages:

Significantly lower installation costs

Flexible configuration and strong adaptability

Visible cables for easy inspection

Optimized heat dissipation and moisture prevention

Multiple material options (e.g., fiberglass, PVC) to meet corrosion resistance needs

Lightweight design reduces overhead installation costs

Some models support direct burial installation

By selecting the appropriate type of cable tray, a safe, reliable, and cost-effective cable management solution can be achieved for various application scenarios.

Post time: Nov-14-2025