Cable Tray vs. Cable Trunking: Critical Distinctions for Procurement Professionals

A Selection Guide for Industrial & Building Electrical Integration

In electrical infrastructure procurement, confusing Cable Trays with Cable Trunking may trigger project cost overruns and installation failures. As decision-makers, understanding their fundamental differences is paramount for risk control.

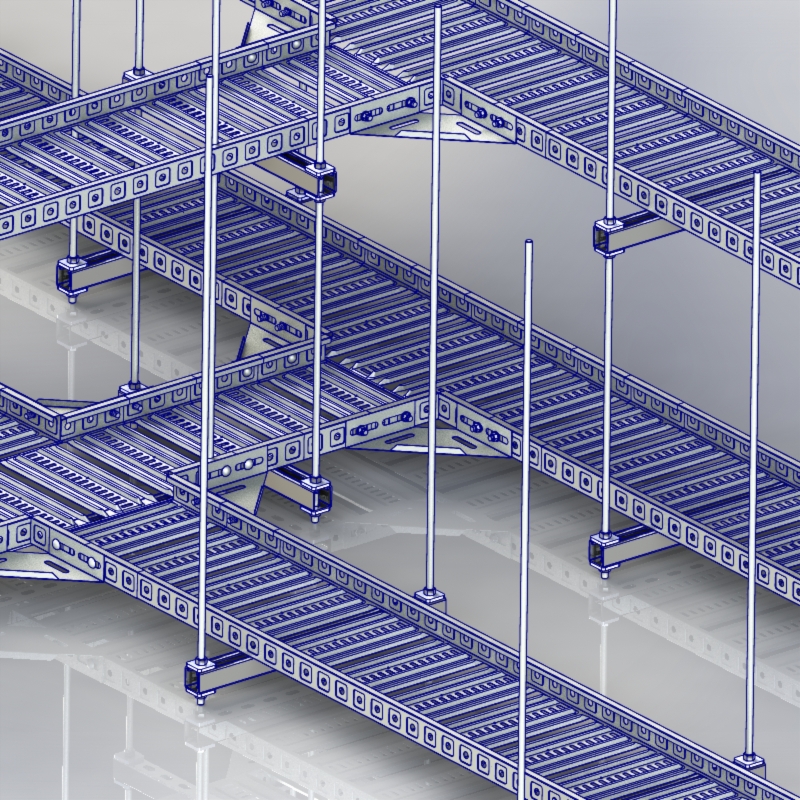

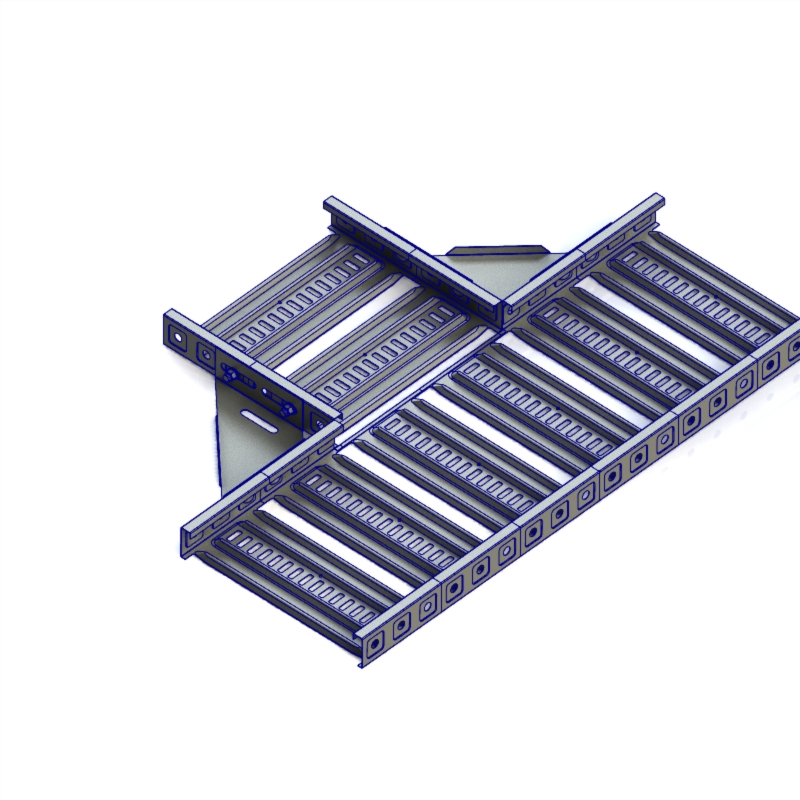

I. Structural Divergence Dictates Application

Cable Tray: Industrial-grade open structures (ladder/mesh type) or semi-enclosed tray systems, bearing capacity >500kg/m. Core value lies in high load-bearing, superior heat dissipation, and easy maintenance – ideal for power cables in data centers, power plants, and petrochemical facilities.

Cable Trunking: Building-level enclosed PVC or thin-steel channels, capacity typically <50kg/m. Designed for concealed routing and basic protection, suitable only for lighting/low-voltage circuits in offices or malls.

II. Costly Procurement Pitfalls

Misjudged Protection Levels

Open trays (IP30) used in chemical plants accelerate cable corrosion (>30% lifespan reduction);

Trunking (IP54) cannot replace trays’ impact resistance in heavy machinery zones (require IEC 61537 Category C certification).

Load Capacity Mismatch

A port project incurred ¥800k rework costs after trunking collapsed under high-voltage cables. Procurement must verify:

Trays: Third-party load test reports (ASTM D638/GB/T 2951.11)

Trunking: Dynamic load rating (≥1.5x safety factor in vibrating environments)

III. Data-Driven Procurement Framework

Parameter Cable Tray Threshold Trunking Threshold

Cable Diameter ≥20mm ≤10mm

Circuit Amperage ≥250A ≤63A

Ambient Temperature -40℃~120℃ (galvanized) -5℃~60℃ (PVC)

Seismic Requirement Mandatory in Zone 9 Prohibited in seismic structures

Procurement Action Plan:

Demand application scenario declarations from suppliers (explicit tray/trunking scope)

Require BIM load simulation for trays (deformation < L/200 under actual cable layout)

Trunking orders must include fire certification (GB 8624 B1 mandatory for civil buildings)

Conclusion: Cable trays are the “steel highways” of industrial power transmission, while trunking serves as “plastic sidewalks” for building wiring. Procurement must establish a technical evaluation system centered on load, environment, and lifespan to prevent supply chain risks caused by conceptual confusion.

→ For all products,services and up to date information,please contact us.

Post time: Aug-11-2025