Right Way To Selecting the Right Galvanized Cable Ladder

In the field of electrical infrastructure, galvanized cable ladders serve as a core component for supporting and managing cables. Valued for their robust and versatile nature, they are the ideal choice for a wide range of applications including data centers, power plants, commercial buildings, and industrial plants. With numerous models available on the market, selecting the right product for your specific needs is crucial. As a significant supplier in the industry, we have compiled this comprehensive selection guide to help you systematically understand the key decision-making points and make the most informed choice.

This article will provide a full-range reference from the following aspects:

- Overview of Galvanized Cable Ladder

- Core Selection Considerations

- Importance and Application Value

- Installation Guide Summary

- Introduction to Common Matching Accessories

- Conclusion

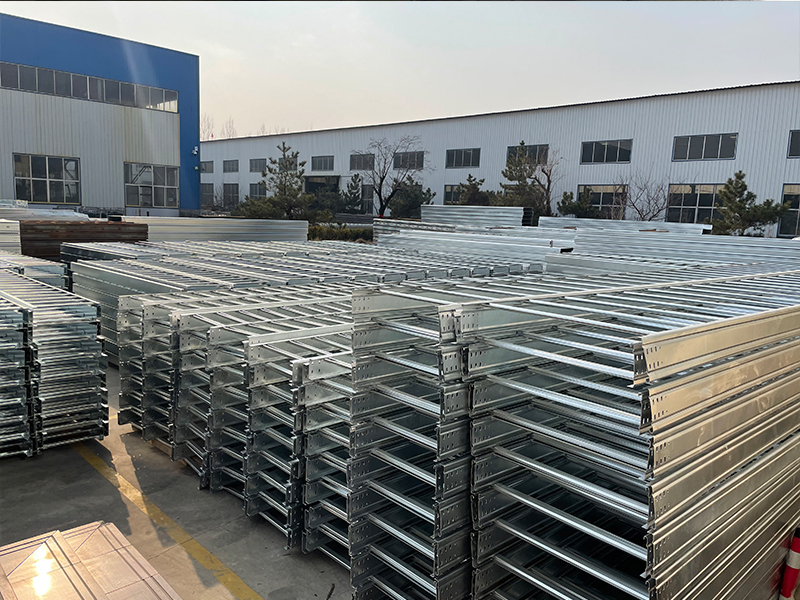

1. Overview of Galvanized Cable Ladder

A galvanized cable ladder is a highly reliable cable support system with strong corrosion resistance, specifically designed for the organized routing and stable support of various wires, cables, and conduits. Its base material is steel, and a sturdy protective layer is formed on the surface through a galvanizing process, significantly enhancing its corrosion resistance and ensuring a long service life for the system. This product combines excellent durability with cost-effectiveness and is easy to install, making it a highly favored solution in cable management applications.

2. Core Selection Considerations

Selecting the most suitable galvanized cable ladder for your project requires a comprehensive evaluation of the following key aspects:

- Load Capacity

This refers to the total weight of cables the ladder can safely support. When selecting a type, ensure its rated load exceeds the actual cable weight to avoid structural risks or operational issues due to overloading. Load capacity is typically related to the ladder’s side rail height and should be calculated based on relevant standards. - Dimensions

The width, height, and length of the ladder directly impact cable capacity and installation convenience. The width must accommodate all cables with appropriate spare capacity, the height should provide sufficient routing space, and the length needs to match the actual routing path. Customization services can usually cover a wide range of size requirements. - Material and Coating

The thickness of the zinc coating (usually measured in microns) directly determines its corrosion resistance. Choosing the appropriate coating type and thickness based on the application environment is crucial:- Pre-galvanized: Cost-effective, with a relatively thin coating, suitable for dry indoor environments without corrosive substances.

- Hot-dip galvanized: A thicker zinc coating formed through an immersion process, offering superior protection, suitable for damp, outdoor, or areas with mildly corrosive substances.

- Operating Environment

The environmental conditions of the installation site, such as humidity, temperature fluctuations, presence of chemical pollutants, or salt, are important basis for selecting the coating type and thickness. Higher protection grades should be prioritized for harsh environments. - Installation Method and Accessories

The fixing method (e.g., wall-mounted, suspended) must be planned in advance, ensuring all installation accessories (supports, connectors, etc.) are compatible with the main structure and meet the structural strength requirements. - Standards and Compliance

The selected product must comply with the local electrical safety codes, building regulations, and relevant industry standards.

3. Importance and Application Value

The core advantage of galvanized cable ladders lies in their excellent durability and corrosion resistance. The surface zinc layer effectively isolates moisture, oxygen, and other corrosive elements, preventing the base material from rusting, thereby significantly extending its service life and greatly reducing long-term maintenance costs and frequency. This makes it a reliable cable support solution for various complex environments, both indoors and outdoors.

4. Installation Guide Summary

Proper installation is fundamental to ensuring system safety and functionality. The main steps include:

- Preparation: Gather all necessary components: ladders, supports, fasteners, and tools.

- Path Planning: Design a reasonable cable routing path and mark the precise locations of support points.

- Cutting: If custom lengths are required, use professional tools for cutting and deburring the edges.

- Fixing Supports: Securely install various types of supports on walls, ceilings, or other supporting structures.

- Placing the Ladder: Position the ladder onto the supports, aligning and leveling it correctly.

- Connection and Fastening: Use specified connectors to reliably join ladder sections and securely fasten the entire assembly to the supports.

- System Grounding: Determine if required by local electrical codes, and effectively ground the ladder system if necessary.

- Cable Installation: Finally, lay the cables orderly on the ladder, securing them with ties or clamps, maintaining proper spacing for heat dissipation.

For complex or large-scale projects, installation by a professional electrician or installation team is highly recommended.

5. Introduction to Common Matching Accessories

A complete ladder system relies on various functional accessories, primarily including:

- Supports: Such as wall-mounted brackets, suspension brackets, and cantilever arms.

- Connectors: Used for straight-section coupling, horizontal or vertical bends, branches (tees, crosses), etc.

- End Caps: Protect the ends of the ladder.

- Fasteners: Dedicated bolts, nuts, etc.

- Other Accessories: Such as cable clamps, reducer sections, dividers, etc., used for cable securing and separation.

6. Conclusion

We hope this guide helps you systematically grasp the key points for selecting galvanized cable ladders. The right choice stems from a comprehensive understanding of the application scenario, technical parameters, and safety standards. We are always ready to provide you with further technical consultation and product services, working together to build a safe and efficient support pathway for your cables.

Post time: Oct-29-2025