U-Channel vs. C-Channel: A Comparative Overview

U-Channel

Structural Features:

Its cross-section forms a flat-bottomed “U” shape, with two sides extending vertically upward, generally of equal height, resulting in a neat and simple form. The flanges are typically short and do not exceed the width of the base.

Common Applications:

Framework and Support: Used in framing structures or reinforcement components where balanced load distribution is important.

Edge Protection: Often applied to protect the edges of boards and panels.

Cable Management: Serves as raceways to neatly organize wires and cables.

Decorative Trim: Widely used for edging and finishing in furniture and architectural decoration.

Key Advantages:

Simple structure, easy to process and install.

Highly versatile and adaptable to various scenarios.

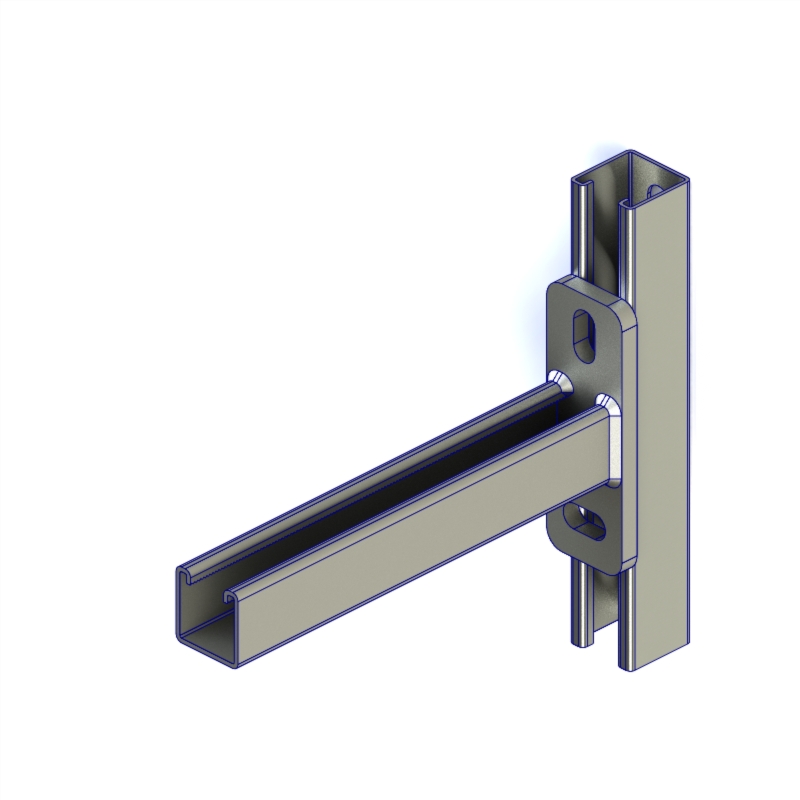

C-Channel

Structural Features:

The cross-section is “C”-shaped, with a flat base and two flanges extending outward. The flanges are usually longer and may feature inward-curled or slanted edges, enhancing overall rigidity.

Common Applications:

Building Framework: Frequently used in load-bearing structures such as wall studs, roof trusses, and floor joists.

Transportation Equipment: Commonly employed in the manufacturing of vehicle chassis and frames.

Heavy Machinery: Provides foundational support frames for large equipment.

Bridges and Walkways: Suitable for structures with higher load requirements, such as footbridges and industrial platforms.

Key Advantages:

Stable structure with excellent load-bearing performance.

Flange dimensions can be flexibly adjusted to meet different support needs.

Key Differences

Cross-Sectional Shape:

U-Channel: Symmetrical U-shape with straight, parallel sidewalls.

C-Channel: C-shape with longer flanges, often featuring specialized edge configurations.

Mechanical Performance:

U-Channel: Generally used for light to medium load scenarios.

C-Channel: Structurally stronger, suitable for high load-bearing applications.

Application Fields:

U-Channel: Commonly found in general-purpose scenarios such as auxiliary fastening, edge treatment, and trim.

C-Channel: Primarily used in main structural functions, often seen in construction, transportation, and other heavy-load fields.

Conclusion

These two types of profiles each have their focus in engineering construction: the U-channel excels in flexibility and versatility, making it suitable for auxiliary functions, while the C-channel stands out with its structural strength, often used in critical load-bearing components. Selecting the appropriate profile based on specific requirements can effectively ensure both the quality and cost-efficiency of a project.

Post time: Nov-03-2025