Why Ladder-Type Cable Trays Are an Ideal Choice for Outdoor Projects?

In today’s fast-paced industrial and construction sectors, a reliable and efficient cable management system is essential—especially for outdoor applications. Ladder-type cable trays, known for their durability and adaptability, have become the preferred solution for many such projects.

This article explains why ladder-type cable trays are particularly well-suited for outdoor use and offers practical insights for end-users.

What Are Ladder-Type Cable Trays?

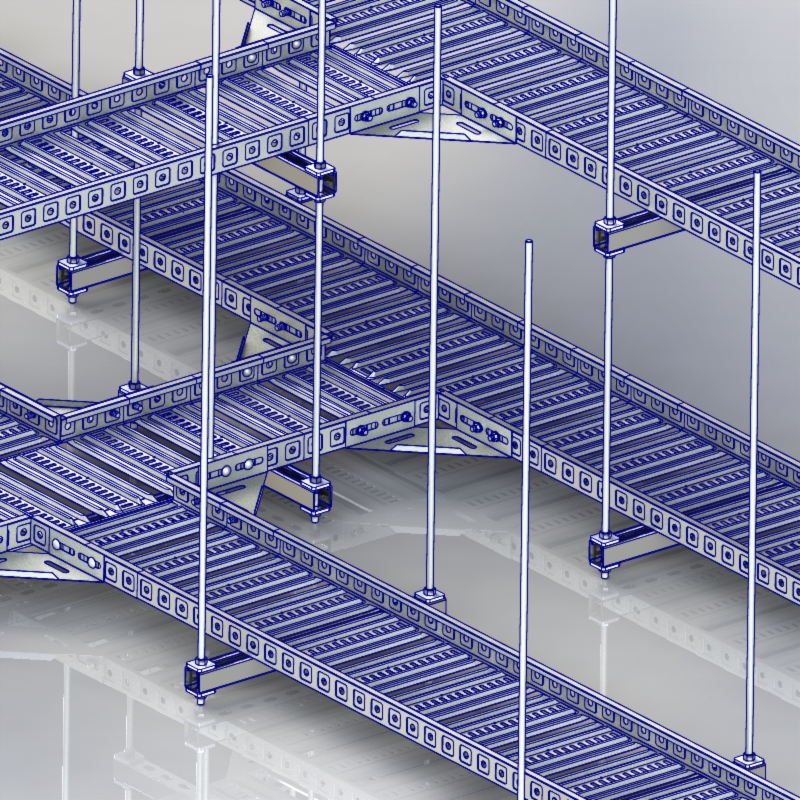

Ladder-type cable trays are a common type of cable support system consisting of two longitudinal side rails connected by transverse rungs, forming a ladder-like structure. This open design not only simplifies installation and maintenance but also promotes effective heat dissipation. They are especially suitable for supporting heavy and numerous cables while ensuring organization and safety.

Why Choose Ladder-Type Cable Trays for Outdoor Projects?

1. Exceptional Durability and Load-Bearing Capacity

Ladder-type cable trays are typically made from high-quality materials such as galvanized steel, stainless steel, or aluminum, offering excellent corrosion resistance. They can withstand long-term exposure to harsh outdoor conditions like sun, rain, and wind. Their robust structure reliably supports large cable loads, ensuring system stability.

2. Superior Ventilation and Heat Dissipation

The open design allows ample airflow, effectively preventing cables from overheating and aging due to high temperatures. This is particularly important in outdoor power systems, significantly extending cable service life.

3. Flexible Installation and Easy Maintenance

The ladder structure allows cable access and fixing from multiple points, making it highly suitable for outdoor projects that require frequent changes or expansions. Inspection, replacement, or addition of cables becomes more convenient and efficient.

4. Cost-Effectiveness

Compared to other types of cable management systems, ladder-type trays involve lower installation costs and require less labor. Their long service life and low maintenance needs further reduce the total cost of ownership, making them an economical choice for large-scale outdoor projects.

Real-World Application: Solar Power Plant in Rajasthan

A solar power plant in Rajasthan, India, serves as a typical example of the successful application of ladder-type cable trays. The project required extensive cabling to connect solar panels to the grid, all while facing extreme heat and frequent sandstorms.

Main Challenges:

Harsh climate: high temperatures and sandstorms;

Long-distance cable runs requiring strong support;

High demand for cable heat dissipation.

Solution:

The project opted for galvanized steel ladder-type cable trays. Their corrosion and weather resistance perfectly adapted to the outdoor environment, while the open design ensured effective heat dissipation, minimizing the risk of overheating. Additionally, the ease of installation helped accelerate project progress, delivering significant economic benefits.

Conclusion

Ladder-type cable trays, with their advantages in durability, heat dissipation, ease of installation, and cost-effectiveness, offer an ideal cable management solution for outdoor applications. Even under the most demanding conditions, they provide reliable support and effective protection for cables.

Frequently Asked Questions

1. What are ladder-type cable trays?

Ladder-type cable trays are a ladder-like structure consisting of two side rails and transverse rungs, used to support, lay, and manage cables. They are especially suitable for medium- to heavy-load applications and outdoor environments.

2. Why are they particularly suitable for outdoor projects?

Due to their weather-resistant construction, excellent ventilation and heat dissipation, and ease of installation and maintenance, they perform reliably in various harsh weather and environmental conditions.

3. Can ladder-type cable trays be customized?

Yes, they can be customized in size, material, and structural configuration to meet specific project requirements.

Post time: Sep-12-2025