Itreyi yekhebulaIdlala indima ebalulekileyo ekulawuleni ngokufanelekileyo nangokukhuselekileyo iintambo kunye neentambo kwiindawo ezahlukeneyo zoshishino kunye nezorhwebo. Inika inkxaso, ukhuseleko, kunye nokulungelelanisa iintambo, isebenza njengendlela engabizi kakhulu kuneendlela zemveli ezifana neenkqubo ze-conduit. Ukukhetha izinto zeetreyi zentambo kubalulekile ekumiseleni ukuqina kwazo, ukumelana nokugqwala, kunye nokusebenza ngokubanzi. Eli nqaku lijolise ekuthelekiseni izibonelelo kunye nokungalungi kweendlela ezimbini ezidumileyo:itreyi yekhebula le-aluminiyamkwayeitreyi yentambo yentsimbi engagqwaliyo.

Iitreyi zekhebula ze-aluminium zaziwa kakhulu ngokuba lula kwazo kwaye zihlala ixesha elide. Ubunzima bazo obuphantsi buzenza kube lula ukuzifaka, nto leyo enciphisa iindleko zomsebenzi nezokuthutha. Njengoko zingenamagnethi, iitreyi ze-aluminium ziluncedo kakhulu kwiindawo apho ukuphazamiseka kwe-electromagnetic kunokubangela iingxaki. Zikwamelana nokugqwala ngokwemvelo, ngenxa yokwenziwa komaleko we-oxide okhuselayo kumphezulu wazo. Olu mgangatho luzenza zilungele ukusetyenziswa ngaphandle, njengoko zinokumelana neemeko zemozulu ezinzima, kuquka nemitha ye-UV. Ukongeza, iitreyi zekhebula ze-aluminium zihlala zinesiphelo esigudileyo nesinobuhle, nto leyo eyenza zibe lukhetho olubonakalayo kwiindawo ezininzi zokufakelwa.

Nangona kunjalo, iitreyi zekhebula ze-aluminium nazo zineengxaki ezimbalwa. Nangona zikwazi ukumelana nokugqwala, azikhuselekanga ngokupheleleyo kuzo. Kwiindawo ezinomhlwa kakhulu, iitreyi ze-aluminium zinokufuna amanyathelo okhuseleko ongezelelweyo, njengeengubo, ukuthintela umonakalo. Enye into ekufuneka iqwalaselwe ngamandla aphantsi oomatshini xa kuthelekiswa nezinye izinto, nto leyo enokunciphisa amandla azo okuthwala umthwalo. Ke ngoko, kubalulekile ukuvavanya ubunzima kunye nobungakanani beentambo ukuqinisekisa ukuba itreyi inokuzixhasa ngokwaneleyo.

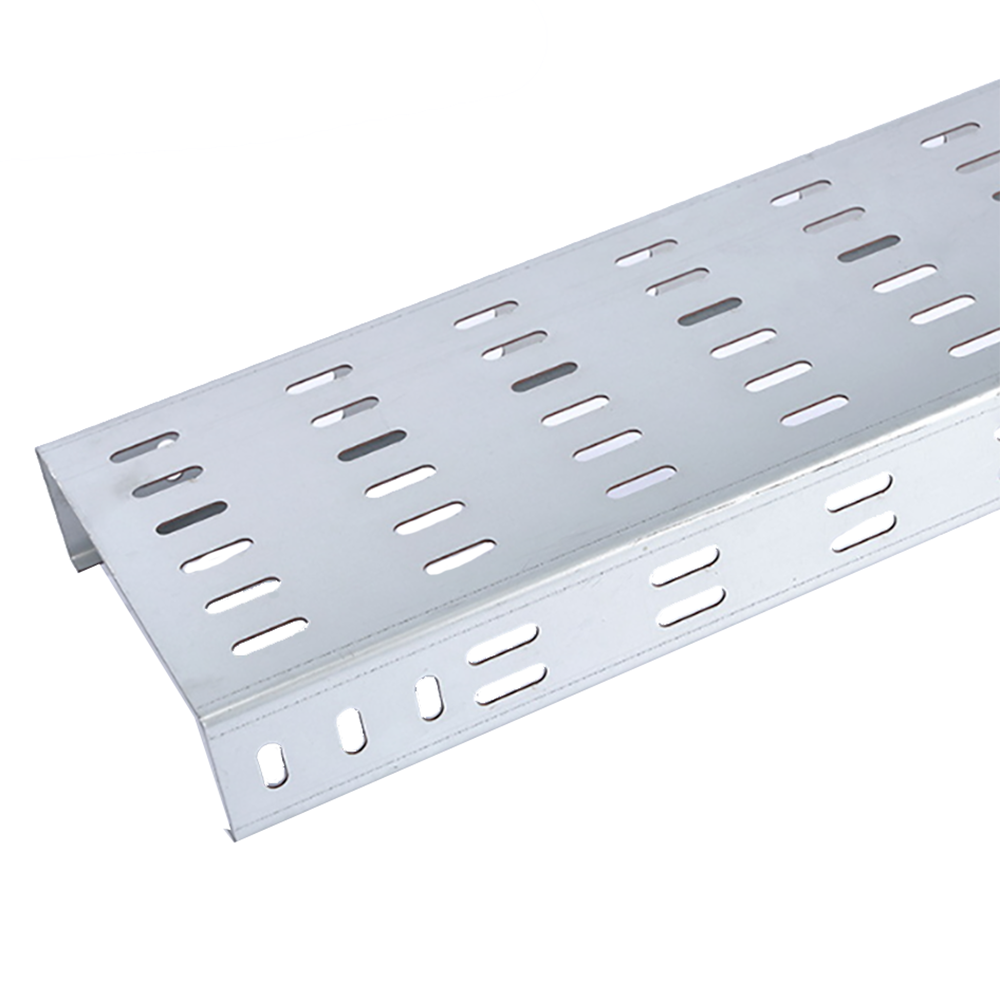

Kwelinye icala, iitreyi zekhebula zentsimbi engagqwaliyo zinika amandla agqwesileyo kunye nokuqina. Zinomthamo ophezulu wokuthwala umthwalo kwaye zinokuthwala iintambo ezinzima kunye neenkqubo zocingo. Ukongeza, iitreyi zentsimbi engagqwaliyo zinokumelana okungaqhelekanga nokugqwala, nto leyo ezenza zifaneleke kwiindawo ezifuna kakhulu, kuquka izityalo zeekhemikhali kunye nokufakelwa kolwandle. Ukumelana kwazo nokugqwala kuphuculiswa ngakumbi ziindlela zokukhetha iingubo ezikhethekileyo kunye nokugqitywa, njenge-galvanization eshushu.Iitreyi zentambo zentsimbi engenasicizikwagcina ukuthembeka kwazo nokuba kumaqondo obushushu aphezulu, nto leyo ezenza zibe lukhetho oluthembekileyo kwiindawo ezifakelwe umbane.

Nangona iitreyi zekhebula zentsimbi engagqwaliyo zinezibonelelo ezininzi, azinazo iingxaki ezimbalwa. Enye into exhalabisayo kukuba zibiza kakhulu xa zithelekiswa neetreyi ze-aluminium. Intsimbi engagqwaliyo yinto ekumgangatho ophezulu, enegalelo ekwandeni kweendleko zokuvelisa. Ubunzima obongezelelweyo beetreyi zentsimbi engagqwaliyo bukwenza uthutho kunye nokufakwa kube nzima kwaye kubize kakhulu. Ngaphezu koko, iitreyi zentsimbi engagqwaliyo zichaphazeleka lula kukutsalwa kwamandla emagnethi, nto leyo enokuthintela ukusetyenziswa kwezinye izinto. Kwiindawo ezineentsimi ze-electromagnetic ezinamandla, ezinye izinto okanye iindlela zokumisa umhlaba zinokufuneka ukulawula ukuphazamiseka kwemagnethi ngokufanelekileyo.

Ukuqukumbela, zombini iitreyi zekhebula ze-aluminiyam kunye neetreyi zekhebula zentsimbi engagqwaliyo zibonelela ngeenzuzo kunye neengxaki ezikhethekileyo. Ukhetho lokugqibela luxhomekeke kwizinto ezahlukeneyo ezifana nokusetyenziswa, uhlahlo lwabiwo-mali, kunye neemeko zokusingqongileyo. Iitreyi zekhebula ze-aluminiyam zibalaseleyo ngokukhanya kwazo, ukumelana nokugqwala, kunye nokuthandeka kobuhle ngexabiso eliphantsi. Kwelinye icala,iitreyi zekhebula zentsimbi engagqwaliyozibonelela ngamandla aphezulu, ukuqina, kunye nokumelana neemeko ezinzima, ngelixa zibiza kakhulu. Ukuvavanya ezi zinto kunye nokubonisana neengcali kunokunceda ekuchongeni ukhetho olufanelekileyo kwiprojekthi nganye ethile.

Ixesha lokuthumela: Oktobha-12-2023