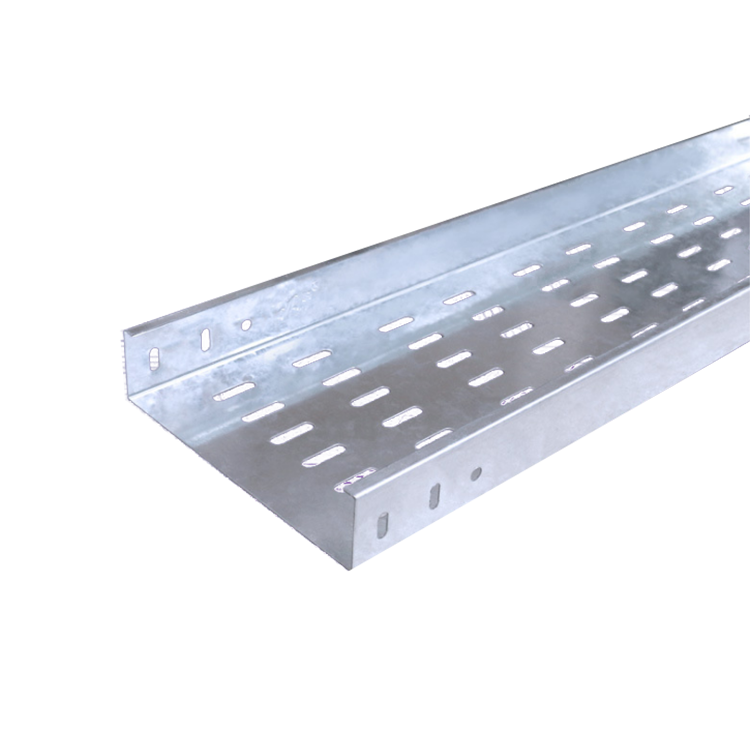

ODM Supplier of GI Perforated Cable Tray for Your Project Needs

When it comes to organizing and supporting your cabling needs, I’ve found that the GI perforated cable tray is an essential choice. Crafted from durable galvanized iron, these trays provide excellent ventilation and efficient cable management, making them ideal for various industrial applications. I often recommend these trays because of their versatility and strength, ensuring that the cables are securely supported while minimizing any risk of overheating. As an ODM supplier, I understand the importance of tailored solutions. We can customize the cable trays to meet your specific requirements, whether it's the size, coating, or design. Partnering with us means you'll get high-quality products that fit seamlessly into your operation. Our commitment to reliability and efficiency ensures that your installation goes smoothly, allowing you to focus on what you do best. Let’s work together to enhance your cable management system with our GI perforated cable trays!

gi perforated cable tray Supplies the World\u2019s Top Brands Factory-Direct Excellence

In today's dynamic industrial landscape, the demand for high-quality cable management solutions is more critical than ever. Among the various options available, perforated cable trays stand out for their versatility and efficiency. Designed to support and manage cables safely, these trays provide an indispensable solution for industries ranging from construction to telecommunications. By offering a sturdy framework, they ensure easy installation, maintenance, and future adjustments, making them a preferred choice for top brands globally. What sets exceptional manufacturers apart is their commitment to factory-direct excellence. By sourcing materials and managing production in-house, they can ensure strict quality control, transparency, and innovation throughout the process. This approach not only enhances product reliability but also drives cost efficiency, allowing businesses to meet budgetary constraints without compromising on quality. As a result, global buyers can confidently select products that align with stringent industry standards, thereby optimizing their operational efficiency. Additionally, with advancements in technology, manufacturers are continually improving their perforated cable trays to meet specific industry requirements. This includes offering customizable solutions tailored to unique applications, ensuring that every client can find the perfect fit for their needs. By investing in these cutting-edge products, businesses enhance their infrastructure while also reinforcing their commitment to safety and sustainability. Ultimately, choosing the right supplier can be the key to unlocking potential benefits, making it vital for global purchasers to partner with manufacturers that exemplify excellence in quality and performance.

GI Perforated Cable Tray Supplies the World’s Top Brands Factory-Direct Excellence

| Material | Dimension (mm) | Load Capacity (kg/m) | Finish | Application |

|---|---|---|---|---|

| GI Steel | 300 x 50 | 60 | Hot-dip Galvanized | Industrial Wiring |

| GI Steel | 600 x 100 | 80 | Electro-galvanized | Commercial Wiring |

| GI Steel | 900 x 150 | 100 | Pre-galvanized | Data Center |

| GI Steel | 300 x 100 | 70 | Hot-dip Galvanized | Electrical Installations |

Related Products