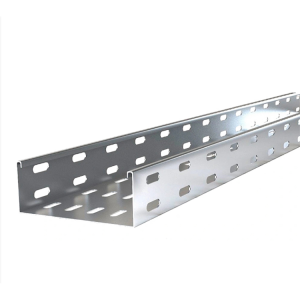

Factory direct sales 300mm Width Stainless Steel 316L or 316 perforated cable tray

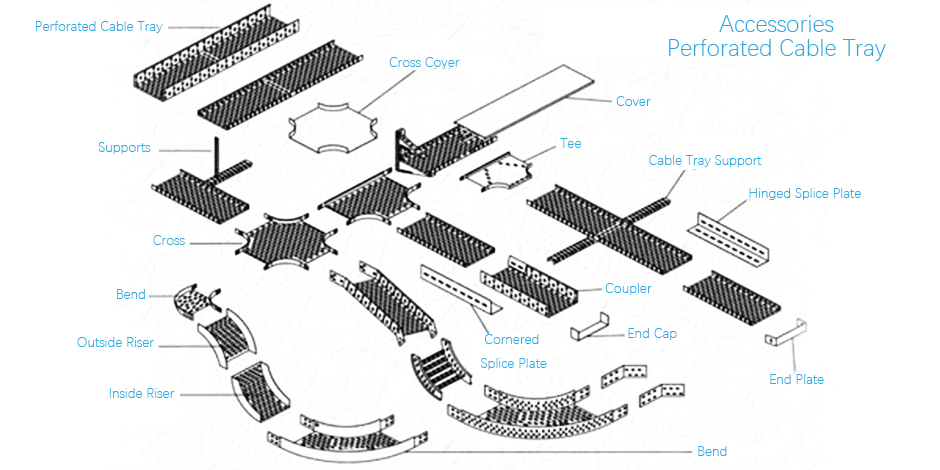

Perforated Cable tray systems are options to wire ways and electrical conductor, which completely enclose wires.

Most cable tray systems are built from a corrosion-resistant metal (low-carbon steel, stainless steel or an aluminum alloy) or from metal with a corrosion-resistant coating (zinc or epoxy).

The choice of metal for any particular connection depends on the connection environment (corrosion and electrical plans) and cost.

If you have list, please send your inqiury to us

Application

Perforated cable trays are capable of maintaining all types of cabling, such as:

1. High voltage wire.

2. Power frequency cable.

3. Power cable.

4. Telecommunication line.

Benefits

1, high fire performance:

Because the steel cable bracket has the characteristics of high fire resistance grade. Therefore, it is not only suitable for general industrial and mining enterprises indoor wiring, installation and maintenance use; It is also suitable for application under special environmental conditions such as flammable and explosive places and high-rise buildings. Therefore, its security is high.

2, strong corrosion resistance:

Because of the high strength of metal materials (especially aluminum profiles), it is not easy to be eroded or oxidized in the general acid-alkaline environment. In addition, because it has good antistatic ability and certain flame retardancy, it can be applied to the occasions with high lightning protection requirements.

3, long service life:

The material of aluminum alloy has a longer life than other materials, and its surface is more beautiful after spray treatment. At the same time, because of its reasonable structure and scientific design, the quality of the product has been very good and the service life has been extended.

4, small size:

Because the aluminum alloy bridge product is light in weight and easy to transport and lift, the product can be assembled and disassembled without lifting and loading equipment during construction.

5. Low price:

Compared with other types of products, the price of aluminum alloy bridge is lower.

6. Beautiful appearance:

The alloying coating after galvanized treatment makes the whole product look more beautiful atmosphere. And this color can be maintained without discoloration and fading.

Parameter

|

Oerdering Code |

W |

H |

L |

|

|

QK1(the size can modified according to project requriements) |

QK1-50-50 |

50MM |

50MM |

1-12M |

|

QK1-100-50 |

100MM |

50MM |

1-12M |

|

|

QK1-150-50 |

150MM |

50MM |

1-12M |

|

|

QK1-200-50 |

200MM |

50MM |

1-12M |

|

|

QK1-250-50 |

250MM |

50MM |

1-12M |

|

|

QK1-300-50 |

300MM |

50MM |

1-12M |

|

|

QK1-400-50 |

400MM |

50MM |

1-12M |

|

|

QK1-450-50 |

450MM |

50MM |

1-12M |

|

|

QK1-500-50 |

500MM |

50MM |

1-12M |

|

|

QK1-600-50 |

600MM |

50MM |

1-12M |

|

|

QK1-75-75 |

75MM |

75MM |

1-12M |

|

|

QK1-100-75 |

100MM |

75MM |

1-12M |

|

|

QK1-150-75 |

150MM |

75MM |

1-12M |

|

|

QK1-200-75 |

200MM |

75MM |

1-12M |

|

|

QK1-250-75 |

250MM |

75MM |

1-12M |

|

|

QK1-300-75 |

300MM |

75MM |

1-12M |

|

|

QK1-400-75 |

400MM |

75MM |

1-12M |

|

|

QK1-450-75 |

450MM |

75MM |

1-12M |

|

|

QK1-500-75 |

500MM |

75MM |

1-12M |

|

|

QK1-600-75 |

600MM |

75MM |

1-12M |

|

|

QK1-100-100 |

100MM |

100MM |

1-12M |

|

|

QK1-150-100 |

150MM |

100MM |

1-12M |

|

|

QK1-200-100 |

200MM |

100MM |

1-12M |

|

|

QK1-250-100 |

250MM |

100MM |

1-12M |

|

|

QK1-300-100 |

300MM |

100MM |

1-12M |

|

|

QK1-400-100 |

400MM |

100MM |

1-12M |

|

|

QK1-450-100 |

450MM |

100MM |

1-12M |

|

|

QK1-500-100 |

500MM |

100MM |

1-12M |

|

|

QK1-600-100 |

600MM |

100MM |

1-12M |

|

If you need know more about perforated cable tray. Welcome to visit our factory or send us enquiry.

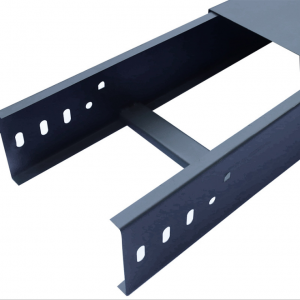

Detail Image

Perforated Cable Tray Inspection

Perforated Cable Tray One Way Package

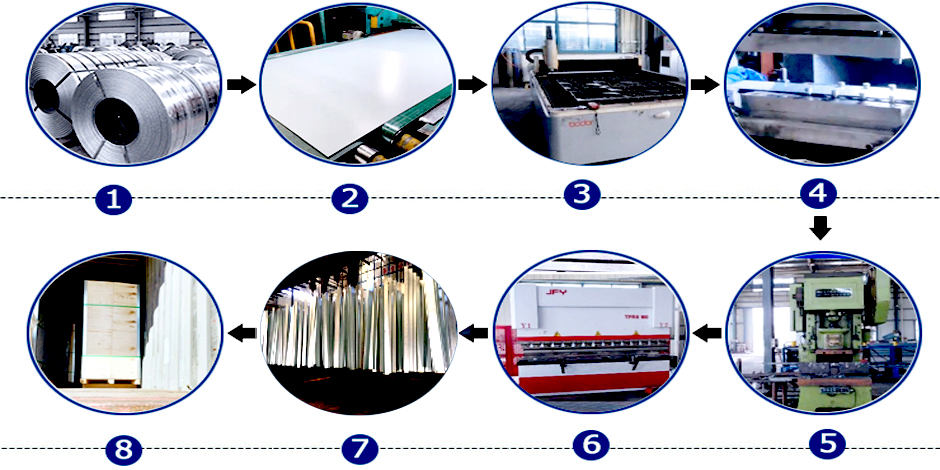

Perforated Cable Tray Process Flow

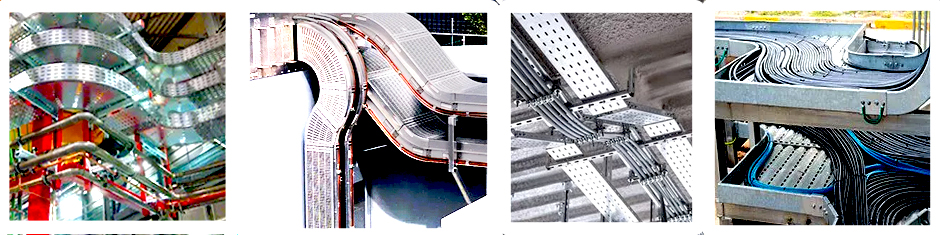

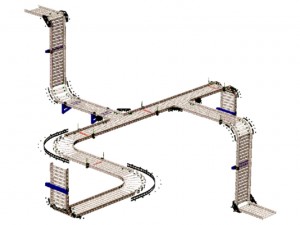

Perforated Cable Tray Project