Glass fiber reinforced plastic cable tray composite fire insulation trough ladder type

As a building material, FRP bridge has the following advantages:

1. Light weight and high strength: compared with traditional metal bridge, FRP bridge has a lower density, so it is light in weight and easy to handle and install. At the same time, it also has excellent strength and rigidity, can withstand large loads, and has strong bending and extrusion resistance.

2. Corrosion resistance: FRP bridge has excellent corrosion resistance, and has strong resistance to most acids, alkalis, salts, humidity, chemicals and corrosive environments.

3. Insulation performance: FRP bridge is a good electrical insulation material with excellent insulation performance. It does not conduct electricity, so it can be widely used in power systems, communication systems and other places that need insulation protection.

4. Weather resistance: FRP bridge has good weather resistance and can resist ultraviolet radiation, high temperature, low temperature and various climatic conditions. It is not easy to age and fade, and has a long service life.

5. Easy installation and maintenance: FRP bridge has the characteristics of lightweight, easy to handle and install. At the same time, it also requires less maintenance, no painting or regular anti-corrosion treatment.

Application

*Corrosion-resistant * High strength* High durability* Lightweight* Fire retardant* Easy installation* Non-conductive

* Non-magnetic* Does not rust* Reduce shock hazards

* High performance in marine/coastal environments* Available in multiple resin options & colors

* No special tools or hot-work permit required for installation

Benefits

Application:

* Industrial* Marine* Mining* Chemical* Oil & Gas* EMI / RFI Testing* Pollution Control

* Power Plants* Pulp & Paper* Offshore* Recreation* Building Construction

* Metal Finishing* Water / Wastewater* Transportation* Plating* Electrical* Radar

Installation Notice:

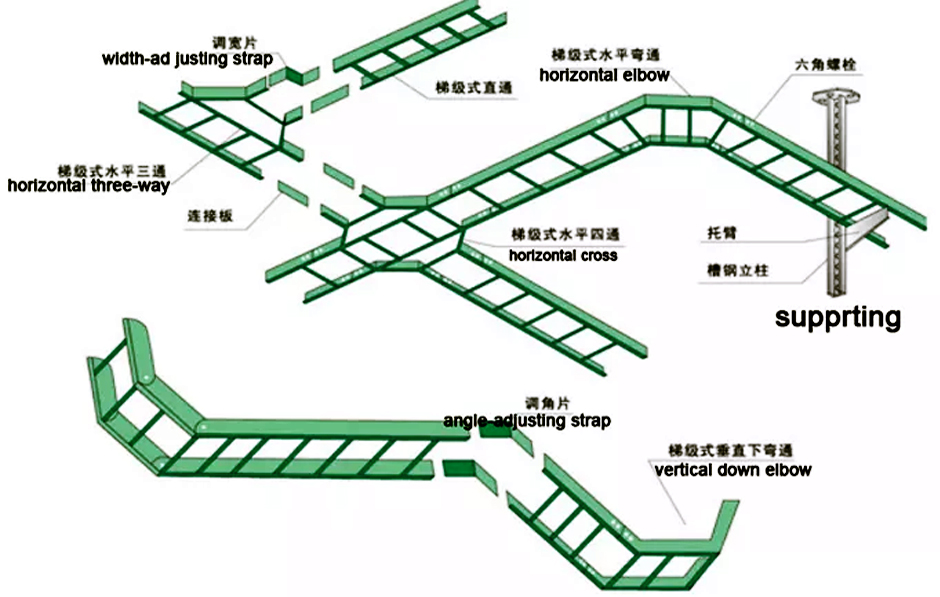

Bends, Risers, T Junctions, Crosses & Reducers can be made from ladder cable tray straight sections flexibly in projects.

Cable Tray systems can be safely employed in places where the temperature ranges between -40°C and +150°C without any change to their characteristics.

Parameter

B:Width H:Height TH:Thickness

L=2000mm or 4000mm or 6000mm all can

| Types | B(mm) | H(mm) | TH(mm) |

|

100 | 50 | 3 |

| 100 | 3 | ||

| 150 | 100 | 3.5 | |

| 150 | 3.5 | ||

| 200 | 100 | 4 | |

| 150 | 4 | ||

| 200 | 4 | ||

| 300 | 100 | 4 | |

| 150 | 4.5 | ||

| 200 | 4.5 | ||

| 400 | 100 | 4.5 | |

| 150 | 5 | ||

| 200 | 5.5 | ||

| 500 | 100 | 5.5 | |

| 150 | 6 | ||

| 200 | 6.5 | ||

| 600 | 100 | 6.5 | |

| 150 | 7 | ||

| 200 | 7.5 | ||

| 800 | 100 | 7 | |

| 150 | 7.5 | ||

| 200 | 8 |

If you need know more about Qinkai FRP reinforced plastic cable ladder. Welcome to visit our factory or send us enquiry.

Detail Image

Qinkai FRP reinforced plastic cable ladder Inspection

Qinkai FRP reinforced plastic cable ladder Package

Qinkai FRP reinforced plastic cable ladder Project