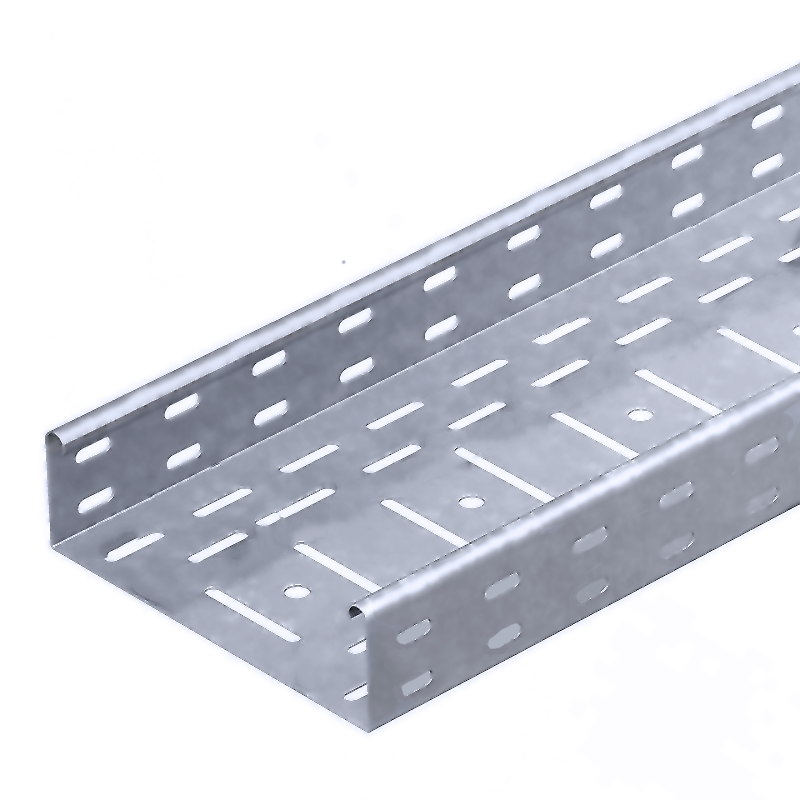

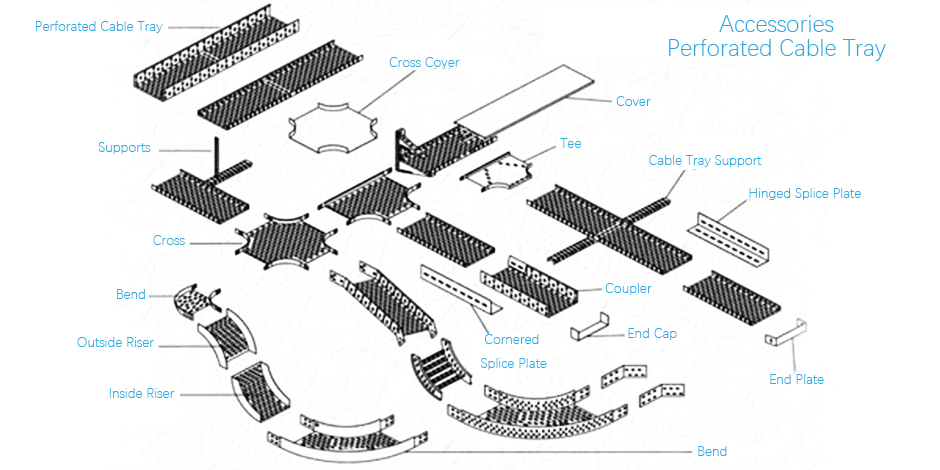

Metal Steel Perforated Galvanized Cable Trays System

The dimensions of perforated cable trays can be adjustable to customers' concrete requirements.With sophisticated technology and first-class facilities, we can manufacture various steel cable tray to meet clients' favour, for instance, galvanized cable tray.

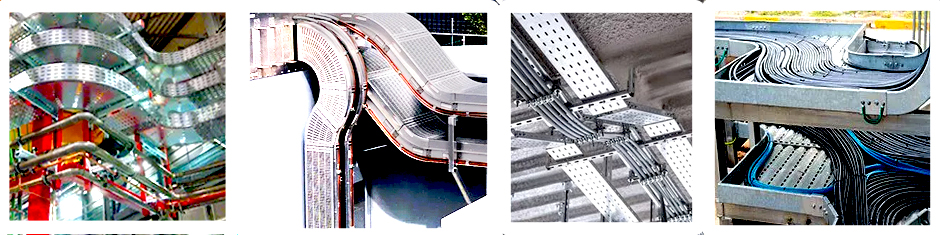

Application Of Cable Trays System

Perforated cable trays are capable of maintaining all types of cabling, such as:

1. High voltage wire.

2. Power frequency cable.

3. Power cable.

4. Telecommunication line.

Benefits Of Cable Trays System

1. Enhanced Ventilation: Evenly spaced perforations in our tray design maximize ventilation, prevent heat build-up and reduce the possibility of cable damage or system failure.

2. Easy to install: Our perforated cable trays are designed with convenience in mind, featuring user-friendly installation methods and adjustable accessories for quick and easy assembly. This saves valuable time and reduces installation costs.

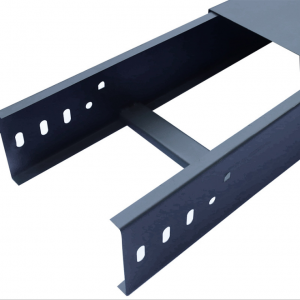

3. Excellent durability: The tray is made of high-quality materials, ensuring long-lasting durability and sturdiness. It can withstand harsh weather conditions, corrosive environments and heavy cable loads without compromising its structural integrity.

4. Flexible Design: Our perforated cable trays are highly customizable, with a variety of accessories available to meet specific requirements. It can be easily modified or expanded, ensuring compatibility with future expansions or cable configuration changes.

5. Improved cable organization: The perforated design allows for easy separation and routing of different types of cables, providing a neat and organized cable management solution. This enhances system reliability and minimizes downtime during maintenance or troubleshooting.

Parameter Of Cable Trays System

| height | 15mm | 50mm | 75mm | 100mm |

| width | 50-600mm | 50-600mm | 50-600mm | 50-600mm |

| standard length | 3m | 3m | 3m | 3m |

If you need know more about perforated cable tray. Welcome to visit our factory or send us enquiry.

Detail Image Of Cable Trays System

Perforated Cable Tray Inspection

Perforated Cable Tray One Way Package

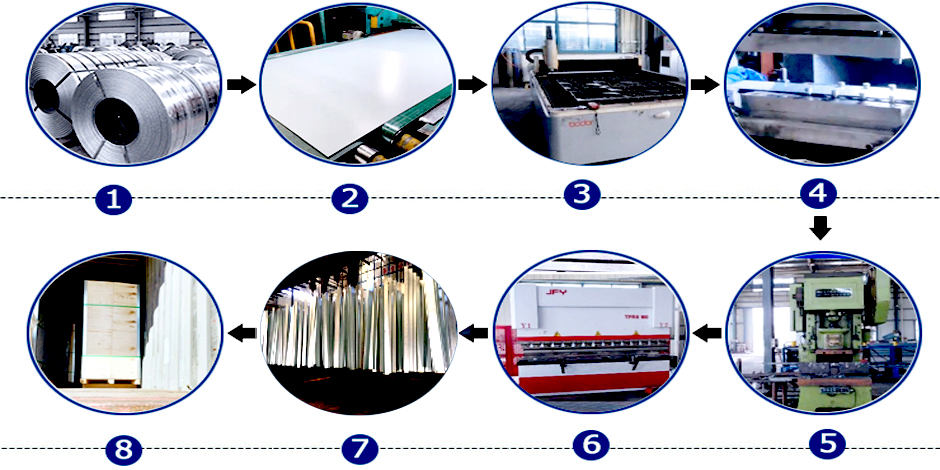

Perforated Cable Tray Process Flow

Perforated Cable Tray Project