Custom Cable Tray Australia: Top Suppliers for Your Needs

As someone who understands the importance of quality in electrical installations, I know that finding the right cable tray can make all the difference. Our custom cable trays in Australia are designed to meet your specific needs, ensuring that your projects run smoothly. Whether you’re working on a large-scale industrial project or a smaller commercial installation, I can help you source the perfect cable management solution. With our extensive network of suppliers, we offer a range of options, from standard trays to custom designs tailored to your specifications. You’ll appreciate the durability and ease of installation, saving you both time and resources. My goal is to support you in selecting the best products that align with your project requirements. Choose us for reliable cable tray solutions that cater specifically to the Australian market, and let’s make your next project a success together. Let’s connect and discuss how we can meet your cable management needs!

Cable Tray Australia Pioneers in the Field Custom Solutions,

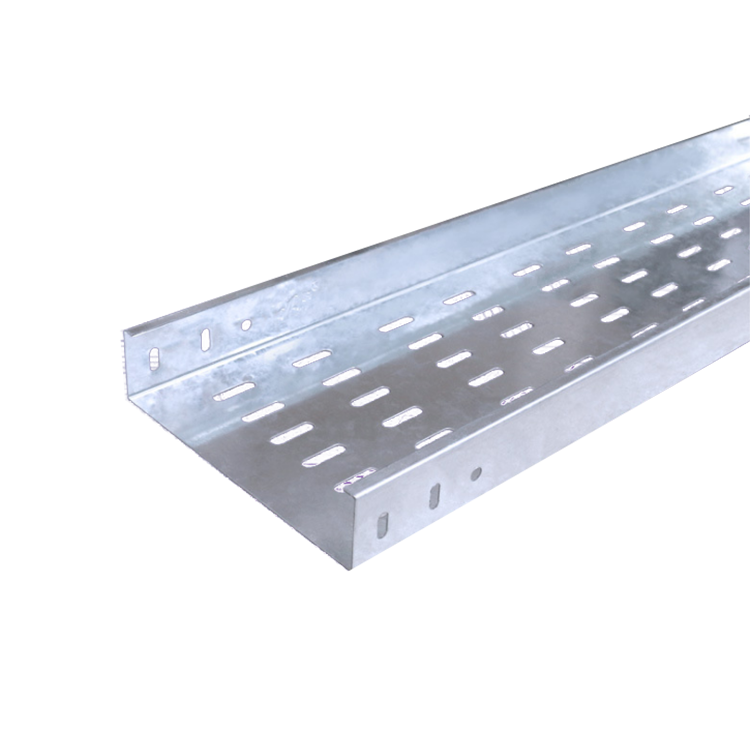

In the fast-evolving landscape of industrial solutions, companies are increasingly looking for customized products that meet their specific requirements. As a result, cable trays have become essential components for efficient cable management in various applications, from commercial buildings to industrial environments. The demand for tailored cable tray solutions is rising, driven by the necessity for enhanced safety, organization, and scalability within electrical systems. Our expertise enables us to address the unique challenges faced by industries around the globe. By collaborating closely with clients, we ensure that our cable trays are designed to fit their exact specifications, taking into account factors such as load capacity, environmental conditions, and installation requirements. This commitment to customization not only streamlines installation but also optimizes the performance of electrical systems, ultimately leading to increased operational efficiency. In addition to our focus on bespoke solutions, we take pride in using high-quality materials and advanced manufacturing processes. This not only guarantees the durability and reliability of our products but also supports sustainability efforts by minimizing waste. By choosing innovative cable tray solutions that prioritize both functionality and environmental stewardship, global buyers can enhance their projects while contributing to a greener future in the industrial sector.

Cable Tray Australia Pioneers in the Field Custom Solutions

| Application | Material | Load Capacity | Customization Options | Application Area |

|---|---|---|---|---|

| Industrial Plants | Galvanized Steel | 2000 kg | Customized Lengths and Widths | Manufacturing, Warehousing |

| Commercial Buildings | Aluminum | 1500 kg | Color Coating Options | Office Spaces, Retail Stores |

| Telecommunication | Stainless Steel | 2500 kg | Special Coatings for Corrosion Resistance | Data Centers, Communication Towers |

| Power Distribution | Fiberglass | 3000 kg | Custom Cutouts for Cable Management | Electric Utility, Renewable Energy |

Related Products