Unperforated Cable Tray Solutions from Top OEM Manufacturers

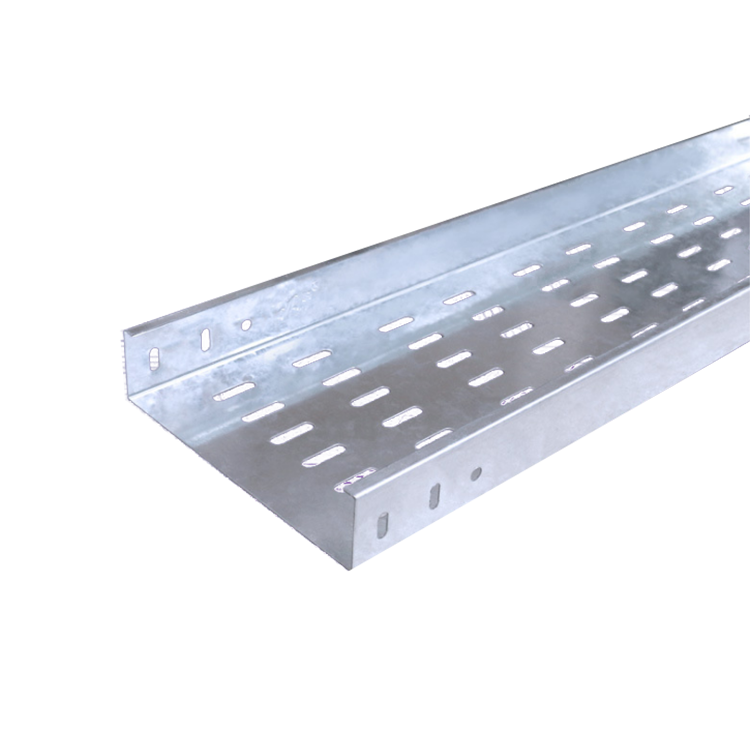

When it comes to efficient cable management solutions, I turn to unperforated cable trays. These trays provide a solid foundation for organizing electrical wiring and cables without compromising on strength. Ideal for various industrial applications, I appreciate how OEM manufacturers design them to meet high quality standards, ensuring reliability and longevity. As I explore different manufacturers, I find their unperforated designs allow for enhanced protection of cables, preventing dust and debris from entering while facilitating easy installation. The smooth surface also minimizes the risk of cable wear and tear. I've seen firsthand how using this type of cable tray can streamline operations and improve overall safety in work environments. If you’re in the market for robust cable management solutions, it's worth considering unperforated cable trays from trusted OEM manufacturers. They align perfectly with our needs for both functionality and durability, ensuring an organized setup for any project.

unperforated cable tray Dominates Pioneers in the Field

In the ever-evolving landscape of industrial solutions, unperforated cable trays have emerged as a pivotal element in the effective management of electrical systems. These trays offer an ideal solution for organizations seeking to streamline their cable management processes while enhancing structural integrity. With a design focused on both functionality and aesthetics, unperforated cable trays are especially beneficial in environments where dust and debris are a concern, minimizing the risk of damage to critical wiring. The advantages of unperforated cable trays extend beyond mere protection. Their solid structure allows for easy installation and reduces installation time, making them a preferred choice among contractors and electrical engineers. Additionally, their versatility accommodates various cable types and sizes, making them suitable for a wide range of applications, from commercial buildings to industrial facilities. With the global demand for efficient electrical solutions on the rise, embracing the use of unperforated cable trays can significantly enhance project profitability and operational efficiency. As the industry continues to innovate, the adoption of these cable management systems not only meets current standards but also anticipates future developments in electrical infrastructure. By choosing unperforated cable trays, procurement professionals can ensure long-term reliability and performance, supporting their organization's commitment to quality and sustainability in every project.

Unperforated Cable Tray Dominates Pioneers in the Field

| Pioneer | Material | Tray Size (inches) | Load Capacity (lbs) | Applications |

|---|---|---|---|---|

| Pioneer A | Steel | 24 x 6 | 200 | Industrial Electric |

| Pioneer B | Aluminum | 30 x 8 | 150 | Commercial Buildings |

| Pioneer C | PVC | 48 x 12 | 100 | Data Centers |

Related Products