Galvanizing Steel Pulley Rollers wheels Roller Pulley for sliding door c channel steel roller

Advantage

One of the standout features of C-channel rollers is their durability. Made from high-quality steel, this roller can withstand heavy loads and resist wear over time. C-groove construction increases the strength of the rollers, providing additional stability and reliability. With this roller by your side, you can trust that your goods will be safe during transportation.

The versatility of C-channel rollers is another significant advantage. It works on a variety of surfaces including concrete, tile and carpet, making it perfect for indoor and outdoor use. Whether you're navigating tight spaces or rough terrain, this roller can handle it. Its smooth-rolling wheels ensure effortless movement, allowing you to carry heavy items without straining your back.

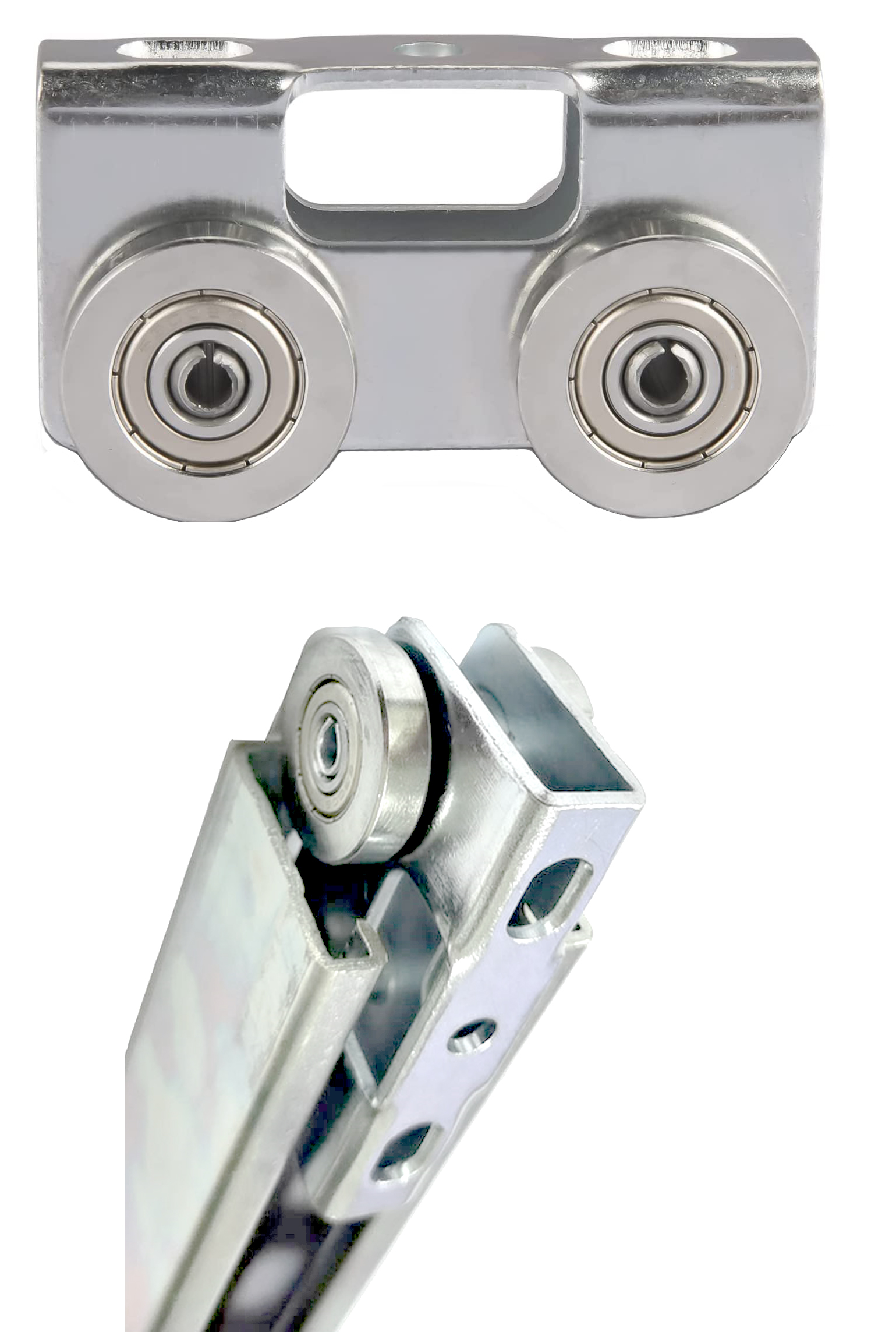

ROLLER TROLLEY 2 WHEEL TROLLEY

[Heavy construction] Two-bearing trolley assembly, made of solid steel hot-rolled carbon steel, is used for impact resistance. Galvanized to ensure the rust resistance of wheeled trolleys. The use process is smooth and noiseless, the bearing and pin are welded firmly, the work is stable, and the strength and quality are incredible!

[Generality] You can use it to install the ceiling trolley system or electric elevator, or use it in your DIY project, which can be used upside down.

[Design load] 150 lbs at 600 rpm; 220 pounds at 300 rpm; 280 pounds at 100 rpm. Breaking strength: 2200 pounds

[Trolley size] The diameter of steel plate hole is 9/16 "(14mm); the thickness is 1/4" (6mm). Applicable to 1-5/8 "wide and all 1-5/8" or higher pillar channels.

![[Heavy construction] Two-bearing trolley assembly, made of solid steel hot-rolled carbon steel, is used for impact resistance. Galvanized to ensure the rust resistance of wheeled trolleys. The use process is smooth and noiseless, the bearing and pin are welded firmly, the work is stable, and the strength and quality are incredible!

[Generality] You can use it to install the ceiling trolley system or electric elevator, or use it in your DIY project, which can be used upside down.

[Design load] 150 lbs at 600 rpm; 220 pounds at 300 rpm; 280 pounds at 100 rpm. Breaking strength: 2200 pounds

[Trolley size] The diameter of steel plate hole is 9/16 "(14mm); the thickness is 1/4" (6mm). Applicable to 1-5/8 "wide and all 1-5/8" or higher pillar channels.](http://www.qinkai-systems.com/uploads/2-wheel-trolley1.jpg)

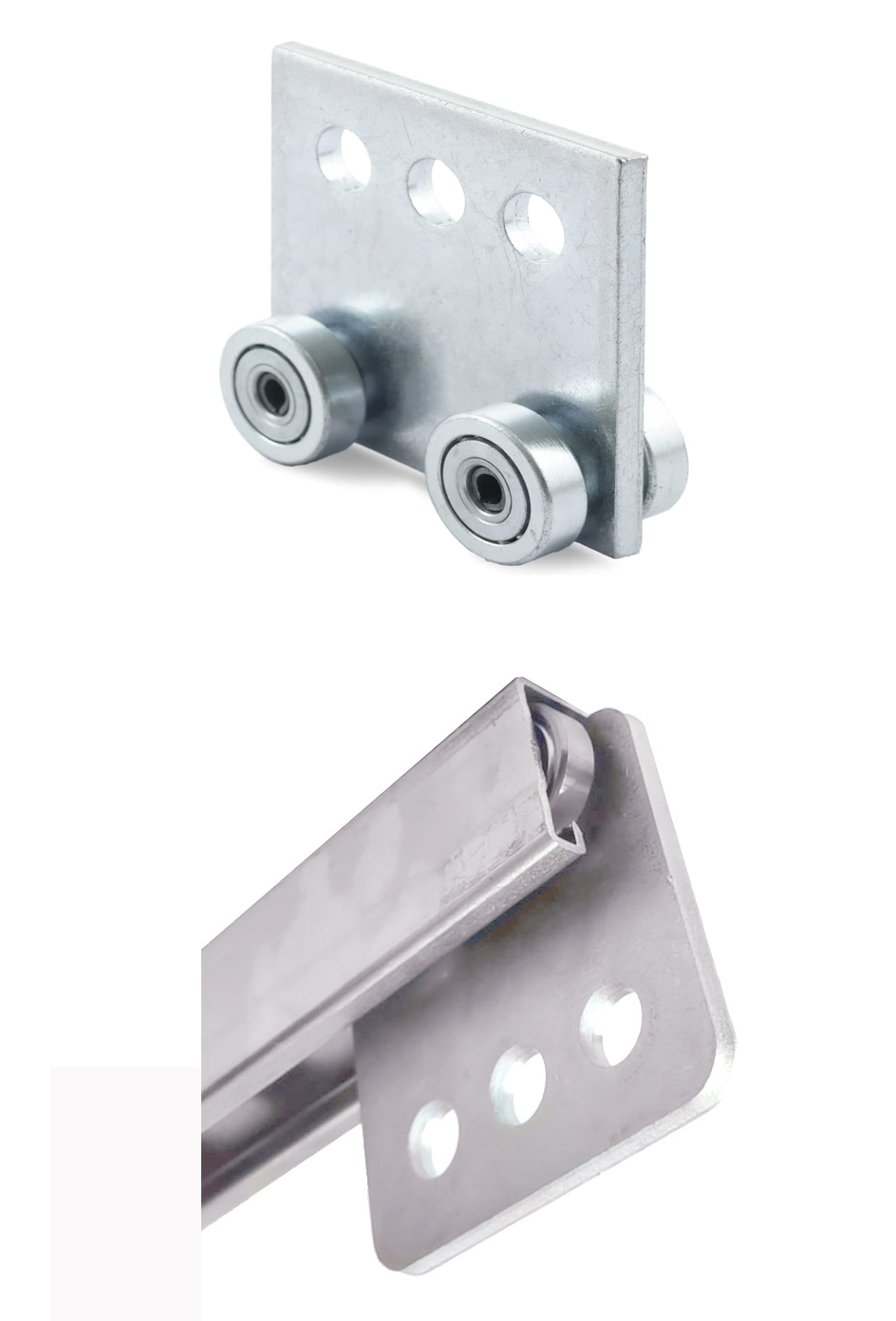

4 Wheel Trolley with 3 holes

High quality materials

High-quality irregular channel steel, made of solid alloy steel, ensures the high strength and smoothness of the wheel pulley.

Solid steel intermediate support with high strength and impact resistance.

Stable operation of slideway

The installation of the standard deep groove ball bearing of the wheeled trolley is very stable and noiseless. The bearing is welded and positioned to ensure the stability of work.

There are 3 mounting holes on the underside of the wheel trolley, which are conveniently positioned to install screws without interference.

ROLLER TROLLEY 4 WHEEL TROLLEY

Load bearing design: our trolley assembly is applicable to 1-5/8 "wide and all 1-5/8" or higher pillar channels. The trolley track system can be used for forward and reverse direction. At 100 RPM load, at 300 rpm and speed/- 600 rpm, it can easily reach at least 400 Lb pounds.

Excellent quality: The car passage has very stable chemical properties, and can withstand the corrosion of various corrosive media and organic solvents within a certain temperature and humidity range. In liquid nitrogen (- 196), the super strut car still has a long-term impact. Very high abrasion resistance, impact resistance, high adhesion resistance, and almost no other materials are attached to the product surface.

Easy to use and M5 thread design: the pole slot trolley roller standard deep groove ball bearing is installed. It is designed with three 9/16 inch screw holes, which are located on 1/4 inch thick steel plate. The ceiling trolley system or electric elevator can be installed at will, and the operation is convenient.

Super quiet features and installation precautions: our strut trough trolley is very smooth and noiseless when used. The bearing is welded and positioned to ensure the stability of work. Please note that if the height of the support channel used with the trolley assembly is not high enough, the trolley roller will touch the mounting bolt in the guide rail. It is recommended to use strut channel horizontally.

4 Wheel Trolley with threaded

Simple to use: wheeled trolley is used for 1-5/8 "wide and all 1-5/8" or higher pillar channels, M10 (3/8 inch) bolts are in the middle, 80mm (3.15 inch) long, and the design load is 770 pounds.

High strength: the pin in the strut slot trolley bearing is made of solid alloy steel, which ensures the high strength of the wheel trolley. Solid steel intermediate support, high strength, impact resistance. Galvanized, rust-proof

Smooth operation: the standard deep groove ball bearing of the wheeled trolley is installed, and it is very stable and noiseless when used. The bearing is welded and positioned to ensure stable operation.

Can be used upside down: 3 nuts are prepared in the attachment, so you can use the cart upside down.

Applicable: applicable to 1-5/8 "wide and all 1-5/8" or higher pillar channels

ROLLER TROLLEY 4 WHEEL TROLLEY

One of the unique features of this roller is its adjustable width. With simple adjustments, you can customize the rollers to fit different object sizes and shapes. This versatility maximizes its usability as it can be used for a variety of tasks such as moving appliances, boxes and even large machinery.

When it comes to functionality, C-channel rollers excel. Its ergonomic handle provides a comfortable grip, reduces stress on the hands, and allows for quick and efficient movement. The non-slip surface ensures a secure hold even in wet or slippery conditions. Additionally, the roller's compact design makes it easy to store and transport when not in use.

All in all, the C-channel roller is an excellent tool that combines durability, versatility, and functionality. With its sturdy construction and adjustable width feature, it's the perfect companion for any transport task. Whether you are a professional mover or just need to move heavy items around the house, this roller will undoubtedly make your task easier and more efficient. Invest in a C-channel steel roller today and experience the convenience and reliability it brings to your daily operations.

4 Wheel Trolley

Heavy structure: Our trolley components are made of high-strength solid steel, impact resistant, galvanized, and can provide anti-rust and anti-corrosion protection. It also has a solid bearing steel pin in the strut channel

Safe and stable performance: the four-bearing trolley assembly has welded bearings and pin shafts, providing greater stability for safe use. It uses deep groove ball bearing to ensure that you can operate smoothly without any noise

Long-term use: Each package is equipped with two beam trolleys, achieving a proper balance in quality, durability and performance. They provide low noise operation and are galvanized to provide smooth opening/closing even in the long term

Multi-functional and multi-purpose: Each four-wheel trolley assembly provides 450 pounds of weight support, applicable to 1-5/8 "wide and all 1-5/8" or higher pillar channels. Its diameter hole is 9/16 "(14mm), and the thickness is 1/4" (6mm)

We support you: If you have any problem with the wheel of car component 4, please tell us, and we will help you quickly solve it to ensure your complete satisfaction. Please note: It is recommended that you use the pillar channel horizontally

Qinkai Strut Trolley Package

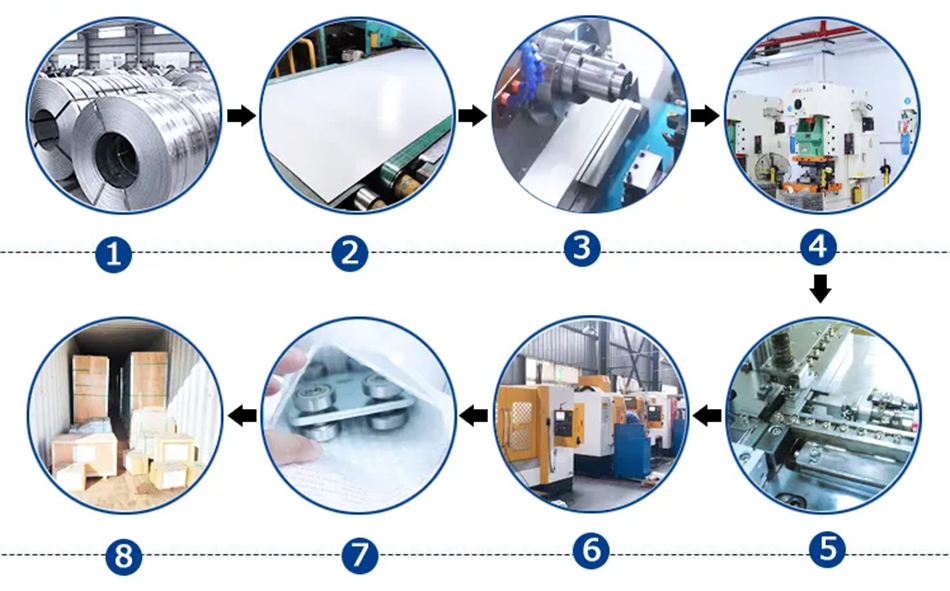

Qinkai Strut Trolley Process Flow