Ground Screw Helical Pile Foundation Solar Structure Helical Ground Screw Pile Photovoltaic

The ground screw pile is a core foundation component for solar photovoltaic (PV) systems installed on the ground. It features advantages such as simple installation, no need for concrete pouring, short construction period, and minimal damage to the ground environment. This guide details the standard installation process, required tools, safety precautions, and quality inspection criteria for solar ground screw piles to ensure the stability and reliability of the PV system foundation.

-

- Verticality Parameter: The vertical deviation of each ground screw pile shall not exceed 1‰ of the pile length, which shall be detected with a theodolite;

- Embedding Depth Parameter: The embedding depth of the pile body shall be in line with the design requirements, with an allowable deviation of ±50mm, and shall be checked with a tape measure;

- Spacing and Position Parameters: The spacing between adjacent piles shall meet the design standards, and the horizontal position deviation of the pile body shall not exceed ±100mm;

- Pile Body Integrity Parameter: The surface of the ground screw pile shall be free from damage, deformation or corrosion. If any defects are found, the pile body must be replaced in a timely manner.

Application

|

Common Problems

|

Causes

|

Solutions

|

|---|---|---|

|

Pile body deviation during driving

|

Uneven soil hardness, improper positioning, or unstable pile driver operation

|

Stop driving immediately, pull out the pile and reposition it; adjust the pile driver to ensure stable operation; pre-treat the uneven soil (e.g., level the soil surface)

|

|

Difficult to drive the pile into the ground

|

Hard soil, gravel in the soil, or insufficient power of the pile driver

|

Replace with a higher-power pile driver (e.g., hydraulic pile driver); pre-drill a small hole in the soil to reduce resistance; remove large gravel in the soil in advance

|

|

Pile body deformation or damage

|

Collision with hard objects during transportation or installation, or excessive driving force

|

Replace the deformed or damaged pile body; avoid collision during transportation and installation; control the driving force of the pile driver to be within the allowable range

|

|

Insufficient bearing capacity of the pile body

|

Insufficient embedding depth, inappropriate pile type selection, or poor soil bearing capacity

|

Increase the embedding depth of the pile body; replace with a multi-helix ground screw pile with stronger bearing capacity; pre-treat the soil (e.g., compact the soil)

|

Please send us your list

In order to help you get the right system, please offer the following necessary info:

1. Dimension of your solar panels;

2. Quantity of your solar panels;

3. Any requirements about wind load and snow load?

4. Array of solar panel

5. Layout of solar panel

6. Installation tilt

7. Ground clearance

8. Ground foundation

Contact us now for customized solutions.

Parameter

|

Parameter Category

|

Parameter Name

|

Specific Requirements/Specifications

|

Detection Tool/Method

|

Remarks

|

|---|---|---|---|---|

|

Basic Product Parameters

|

Material

|

Q235B carbon steel / Q355B alloy steel (optional anti-corrosion treatment: hot-dip galvanizing, galvanizing thickness ≥85μm)

|

Material test report, thickness gauge

|

Corrosion resistance meets GB/T 13912-2020 standard

|

|

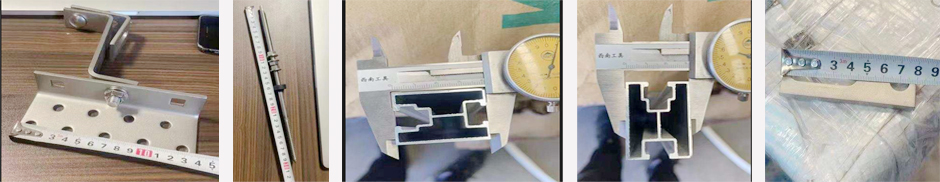

Pile Diameter

|

Common specifications: 89mm, 114mm, 140mm, 168mm; allowable tolerance: ±2mm

|

Vernier caliper

|

Customizable according to project design

|

|

|

Pile Length

|

Common specifications: 1200mm-2500mm; allowable tolerance: ±5mm

|

Tape measure, steel ruler

|

Determined based on local frost line and soil conditions

|

|

|

Helix Specification

|

Helix diameter: 200mm-400mm; helix thickness: 6mm-10mm; number of helixes: 1-3

|

Vernier caliper, tape measure

|

Multi-helix type for higher bearing capacity

|

|

|

Installation Quality Parameters

|

Verticality

|

Vertical deviation ≤1‰ of the pile length

|

Theodolite, level

|

Avoid uneven stress on the pile body

|

|

Embedding Depth

|

Consistent with design requirements; allowable deviation: ±50mm

|

Tape measure, depth gauge

|

Ensure stability against seasonal freezing-thawing

|

|

|

Pile Spacing & Position

|

Pile spacing: 2000mm-3000mm (per design); horizontal position deviation ≤±100mm

|

Tape measure, total station

|

Guarantee installation accuracy of subsequent PV modules

|

|

|

Pile Top Elevation

|

Consistent with design requirements; allowable deviation: ±30mm

|

Level, level rod

|

Adjustable with gaskets if needed

|

|

|

Performance Parameters

|

Vertical Bearing Capacity

|

≥30kN (for φ140×1800mm single-helix pile in common soil)

|

Static load test

|

Varies with soil type and pile specification

|

|

Horizontal Bearing Capacity

|

≥8kN (for φ140×1800mm single-helix pile in common soil)

|

Horizontal load test

|

Ensure resistance to wind load and seismic force

|

|

|

Appearance Quality Parameter

|

Pile Body Integrity

|

No cracks, deformation, or corrosion; welds smooth without slag inclusion

|

Visual inspection, magnifying glass

|

Defective piles must be replaced immediately

|

If you need know more about Qinkai Solar panel roof tile photovoltaic support system . Welcome to visit our factory or send us enquiry.

Detail Image

Qinkai Solar panel roof tile photovoltaic support system Inspection

Qinkai Solar panel roof tile photovoltaic support system Package

Qinkai Solar panel roof tile photovoltaic support system Process Flow

Qinkai Solar panel roof tile photovoltaic support system Project

Write your message here and send it to us